Metal products manufacurer selects Tri-Mer wet scrubber for metalworking dust.

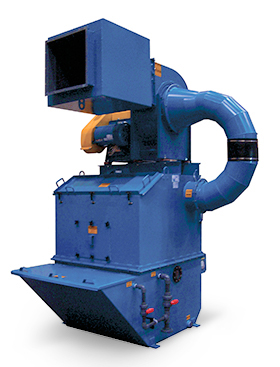

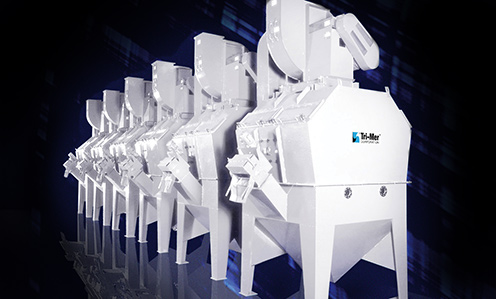

A manufacturer of precision metal components chose a Whirl Wet Scrubber for the collection of particulate from multiple machining operations. The customer debated between an all-polypropylene unit, or a mild steel unit with an epoxy liner, ultimately opting for the polypropylene. (Tri-Mer also manufactures this system in PVC, PVDF and stainless steel.)

Polypropylene is a thermoplastic polymer that's ideally suited to continuous duty equipment such as the Whirl Wet. It is damage-resistant and resilient, and will not delaminate or embrittle over time. The system provides 99%+ efficiency on particles 10.0 microns and larger. It uses very little water.

The Whirl Wet Scrubber chosen is a 4200 cfm Model M, a format with a manual clean-out that is often preferred where dust volumes are low. Tri-Mer also offers the system with an automatically timed drain-down system or, for heaviest dust loadings, the Model MCD (Modular Conveyor Dragout) which allows clean-out without pausing production.