Industrial Dust Collector Systems capture chemical powders.

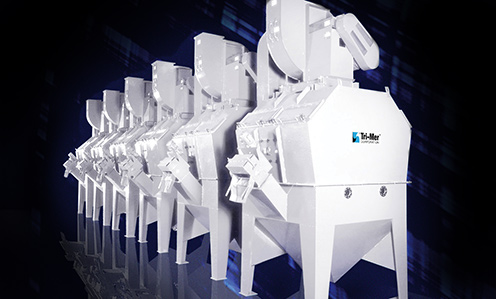

A multinational chemical manufacturer specified Tri-Mer Industrial dust collector technology for a mixing and blending operation. The system provides 99%+ collection efficiency over a wide range of micron sizes.

Whirl Wet industrial dust collection is a leading choice in chemical and pharmaceutical environments, where operation is often continuous and preference is given to equipment with a strong track record of reliability and low maintenance. Whirl Wet is also preferred where dusts are volatile or explosive.

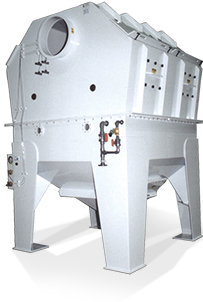

This Whirl Wet system has a capacity of 6300 cfm, and is manufactured in 316 stainless steel. Tri-Mer also manufactures dust collector systems in mild steel, PVC, PP, and PVDF.

This Whirl Wet is a Model H, with an automatically timed drain-down system for easy retrieval of collected particulate. Tri-Mer also offers a manual clean-out format, and, on the other end of the spectrum, the Model MCD (Modular Conveyor Dragout) which allows particulate removal without system shut-down and is widely specified for applications with heavy loadings.