Whirl Wet provides High Efficiency Wet Dust Collection for Erickson Cosmetics.

Production was accelerating at Erickson Cosmetics, a Chicago-based maker of talc and cornstarch-based products for the Mennen Division of Colgate-Palmolive and other companies. The 320,000 sq. ft. plant is highly automated and, while the primary powder line operated within regulatory guidelines for dust control, Todd Nelmark believed there were strong reasons to consider automatic dust collection.

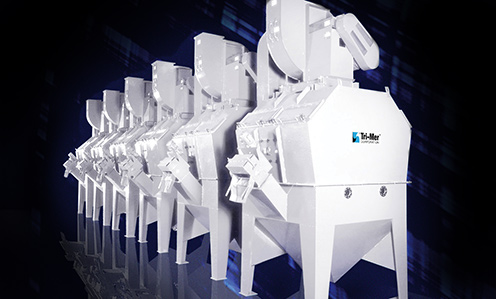

After evaluating several wet dust collection alternatives, Nelmark chose a Whirl / Wet unit made by Tri-Mer Corporation.

The primary challenge was to collect airborne dust while not “pulling” powder material from the fillers. Velocity had to be tightly controlled.

The unit that best served Erickson’s requirements was an 1800 cfm Whirl / Wet. The unit operates only while powders are being filled. Dust is collected from 30 point sources and funneled to the unit. A 10 hp medium pressure fan creates the needed vacuum.

The air is passed under high velocity through a fixed position, dual-opposed blade system. The aggressive mixing of the dust-laden airstream is injected through a linear slot in the lower blade assembly.

Rotation is accelerated, droplets in the airstream are eliminated through a mist eliminator, and particulate is deposited on the bottom of the unit for recovery.

The system proved to be 99%+ effective for the collection of soluble and insoluble particles above one micron.