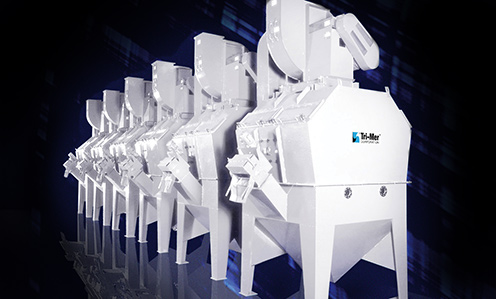

Whirl Wet provides high efficiency wet dust collection for Delphi Automotive.

Tri-Mer dust collection technology is used by Delphi Automotive. Four units were selected as replacements for dry collectors. Each unit serves four grinding (or shot blasting) stations. Capacities range from 425 to 52,500 cubic ft./minute.

The units accommodate very heavy loadings under continuous use, and allow regular maintenance without interrupting production. Equally important, the Whirl Wets eliminate concerns about sparks from hot metal fines – a major maintenance dilemma.

In this application, the Whirl Wets are 99%+ efficient in capturing fines ten microns and larger. Operational advantages of the units include quiet operation, very low water use, and a design free of internal moving parts. This latter point was regarded as beneficial because conventional collectors incorporate spray nozzles, pumps, and disposable bags, all of which increase the time and cost of maintenance.

The Whirl Wets manufactured for Delphi Automotive are PLC-controlled for highest reliability, and continuous monitoring of pressure, flow and water levels.