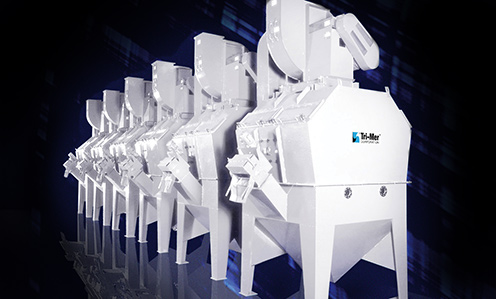

Systems integrator specifies Tri-Mer Whirl Wet Dust Collection System.

A specialist in ingredient handling and mixing systems for the food, beverage and pharmaceutical industries specified a Whirl Wet dust collection system for food dusts.

The unit is a Whirl Wet, manufactured in all-polypropylene, with Allen Bradley controls. (In addition to polypropylene and other engineered plastics, Tri-Mer manufactures the Whirl Wet in stainless steel for these applications.)

Whirl Wet has long been the dust collection system of choice for food and beverage companies for 3 reasons. It has a high collection efficiency: 99%+ for particles 10 microns and larger; 98% for particles 5 microns and larger. It is self-cleaning. And its unique design has no internal moving parts to wear or replace.

The system chosen, a Model H, streamlines the management of collected particulate using an automatically timed drain-down system. Other models offer manual disposal, or, for heaviest dust loadings, an MCD model allows particulate removal without system pause. The system specified for this application has a 3570 cfm maximum capacity.