American Racing Equipment is one of the world’s largest aftermarket wheel manufacturers, offering more than 100 precision-crafted alloy wheel styles.

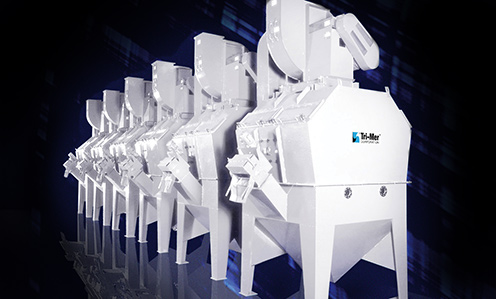

To collect particulate and metal fines from its cutting and grinding operations, American Racing has installed six Model H Whirl Wet dust collectors at its manufacturing facility in Queretaro, Mexico.

The Whirl Wet systems are all-plastic (polypropylene) and operate at 99%+ efficiency. Whirl wet dust collectors are self-cleaning, and do not use “wear” parts such as bags, pumps or nozzles.

They use minimal water, very little energy, and operate virtually maintenance-free.

Whirl Wet dust collectors are well suited for metal fabrication and are used for metal cutting, grinding and sawing operations. They are also used for collecting extremely fine metal dusts from the machining of aluminum or platinum.

Whirl Wet dust collectors are superior to dry collectors wherever exotic metal dusts are generated, because there is no explosion hazard with Whirl Wet dust collection technology.