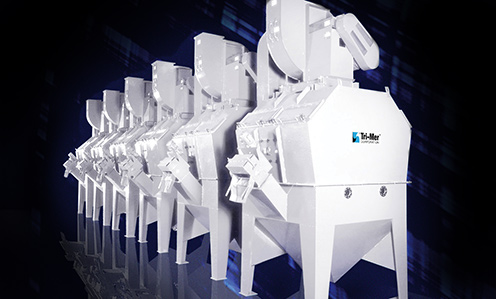

Petrochemicals manufacturer chooses Tri-Mer Industrial Dust Collection System.

A large multinational manufacturer of chemicals, polymers and other petrochemical derivatives chose a Whirl Wet industrial dust collection system to collect particulate from a pellet dryer. The system, a Model H, has a capacity maximum of 5250 cfm.

Whirl Wet uses a unique process to intensely combine water and particulate. The mixture is passed under high velocity through a blade system, where turbulence is increased and rotation is accelerated. Particulate is deposited at the bottom of the unit for recovery or disposal. This Model H has an automatically timed drain-down system to simplify the removal of collected particulate.

Whirl Wet industrial dust collection systems are engineered for low water use, which has made them popular throughout the American west, as well as the Middle East and other regions where water is costly.

This Model H is stainless steel, with a NEMA 12 controls enclosure. Tri-Mer also manufactures the Whirl Wet in mild steel and various engineered plastics.