Whirl Wet Dust Collectors preferred for pill coating operation.

A major multi-national manufacturer of pharmaceuticals and vaccines chose Whirl Wet technology for a pill coating operation. The aqueous sugar solution created heavy loadings of sticky overspray in the 3 micron range. This blinded the existing baghouses after just six batches despite the use of PTFE cartridges – (the best available option for baghouses used in this type of application.)

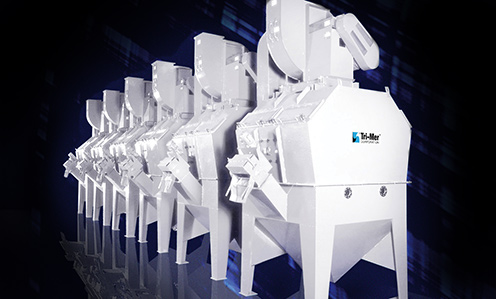

Six 2500 cfm Whirl Wet units were installed. The units are carbon steel, with manual drag-out. Whirl Wet dust collectors are exceptionally well-suited to the collection of dusts three microns and above. Energy generated inside the unit will not allow the system to clog under any operating conditions, and agglomeration and sticky residues never become an issue.

Whirl Wet dust collectors have no internal moving parts; they are also self-cleaning and highly energy-efficient. Water use is low: following the initial charge at the time of installation, only minor water additions are needed to compensate for evaporation and drag-out.

The dust collectors are 99%+ efficient in this overspray collection application. Whirl Wet technology is widely used throughout pharma, for the collection of dusts from crushing, mixing, pelletizing, tabletting and packaging operations. Systems are manufactured in stainless steel and engineered plastics, as well as carbon steel.

For the collection of submicron particulate in pharmaceutical processing, Tri-Mer offers the CCS Cloud Chamber Scrubber.