Harley Davidson shines with Industrial Dust Collector for metalworking and machining operations.

Gabilan Manufacturing produces all the mufflers used on Harley Davidson motorcycles. Recently, the Salinas, CA company installed a Whirl Wet industrial dust collector – its third – to serve a metal polishing operation.

“This operation is critical to chrome plating,” explains Gabilan’s Director of Engineering. “What attracted us to the Whirl Wet industrial dust collector was its polypro construction. Other wet collectors we knew about didn’t hold up very well, no matter what they were coated with. Metal dust fines, plus water, will, sooner or later produce rust in any metal unit. And other non-metal wet collectors we considered were too costly. Whirl Wet had the best design, and was the most competitively priced.”

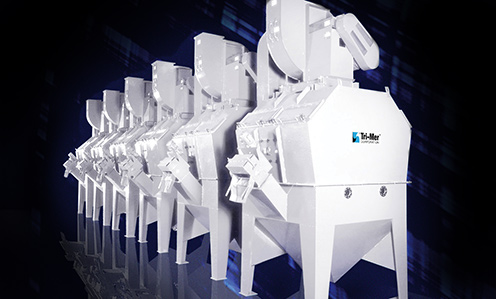

Three Whirl Wet industrial dust collector units are installed in the same facility; all interface with polishing or sanding operations. Collected material is processed through a magnetic filter which separates-out the fines. The system offers significant advantages in terms of housekeeping and clean-up, and is also in line with the company’s ‘safety first’ commitment.