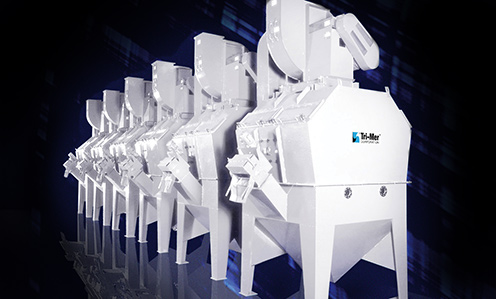

Whirl Wet Dust Collector System chosen for processing and packaging operations.

A leading manufacturer of spices has repeatedly chosen Tri-Mer dust collector technology for use in its processing, weighing and packaging operations. Whirl Wet captures 99% of particles 10.0 micron and larger, and has been widely used in food processing for decades.

The dust collector specified is a 1000 cfm (1050 maximum cfm) Model H, engineered for continuous duty. It has an automatically timed drain-down system for removal of collected material from the hopper. It is one of 3 disposal options offered on the Whirl Wet.

The system is all-polypropylene; Tri-Mer also manufactures its dust collector systems in stainless steel for food and pharma applications. Control is via an Allen Bradley PLC.

The Tri-Mer dust collector design uses very little water; the only make-up water required is what’s needed to compensate for evaporation. Whirl Wets can be supplied alone, or as a package, with material handling.