Horween Leather chooses Whirl Wet Dust Collector for high efficiency and safety.

For leather fines and other lightweight, porous materials, dry collection has been thought to be preferable to wet because of the material’s buoyancy.

Horween Leather Company challenged that assumption. Originally, two baghouse systems collected particulate, but problems arose with each baghouse. First, cold winter dryness caused high levels of static electricity. Resultant sparks in the ducts headed to the baghouse, creating fire risk.

Worse was a problem peculiar to tanning: steel shot embedded in the hides remained through the tanning process and the use of sandpaper on the hides created another fire hazard. The danger was heightened by tanning chemicals.

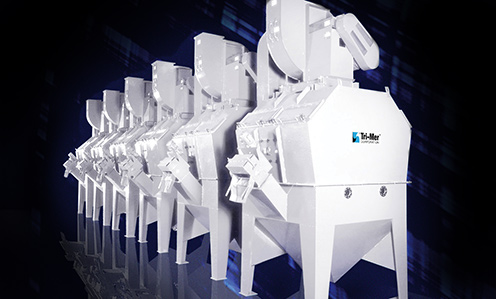

Horween installed a 14,000 cfm Whirl / Wet Dust Collection System, ducting three machines to the unit. The Whirl Wet eliminated the risk of fire and explosion at the finishing stations. With dust collection efficiency of 98.6%, dust throughout the plant was eliminated and product quality improved.