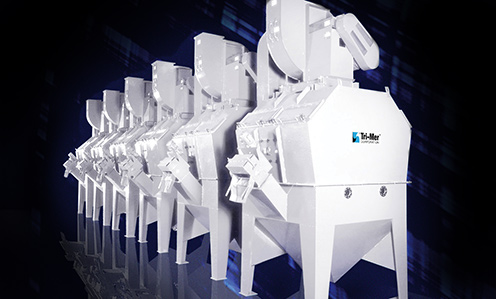

Whirl Wet Dust Collector System chosen by waste management firm.

A company specializing in waste management services, recycling, and de-packaging solutions specified a Model H Whirl Wet Dust Collector System to capture dusts from solid waste processing. Whirl Wet captures 99.0% of particles 10.0 micron in size and 98% of particles 5.0 micron and larger, so it is ideally suited to this application.

This 7350 cfm wet dust collection system is manufactured in all-polypropylene*, a popular choice for this equipment. Polypropylene is a high-strength, monolithic material that won’t corrode, embrittle, or de-laminate. It has very low moisture absorption, and is exceptionally stress and crack-resistant, so it is ideal for environments where accidental impact can occur from material handling devices.

The Model H chosen for this application is one of 3 disposal options offered for the Whirl Wet. The Model H has an automatically timed drain-down system. Other options include the Model M, which has manual clean-out and the MCD (Modular Conveyor Dragout) which is ideal for high dust loading applications, and which has the advantage of continuous operation even during maintenance.

Like all Whirl Wet systems, the Model H has a long history of reliable low-maintenance operation and uses very little water: the only make-up water required is what’s necessary to compensate for evaporation.

* Tri-Mer also manufactures the Whirl Wet in mild steel and thermoplastics, including polypropylene, PVC and PVDF.