Capturing diesel particulate has been an ongoing challenge for the pollution control industry for decades.

Traditional pollution control technologies have operational barriers due to the nature of the diesel particulate and the unique operating environment of the port. These obstacles were complicated by the requirement for high levels of NOx removal at relatively low temperatures.

When applied to ships, these challenges were further compounded by the need to effectively collect the diesel engine exhaust from auxiliary engine smokestacks and convey the exhaust to the treatment system without interrupting loading/unloading and other operations of the ship at-berth.

The METS system has two components. The first component is a stack adaptor or flexible emissions capture device that connects the treatment system to the ship exhaust stack via a flexible pipe. It is placed by a crane that sits on the barge (Figure 1).

Figure 1: CAEM crane and capture device

The specialized capture device connects to the stack in a manner which effectively collects the exhaust while minimizing fugitive outside air (Figure 2).

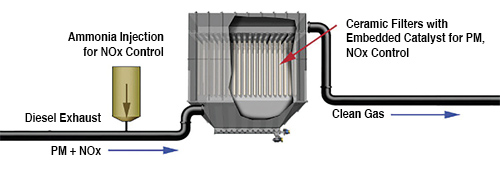

The second component uses Tri-Mer Catalytic Ceramic Filter (CCF) technology to remove the PM and NOx from the exhaust (Figure 3).

Figure 2: METS flexable emissions capture device

Figure 3: METS Catalytic Ceramic Filter (CCF) System

Tri-Mer is the world’s largest manufacturer of multi-pollutant systems employing Catalytic Filters. A simplified flow diagram is shown in (Figure 4).

Figure 4: Catalytic Ceramic Filter (CCF) System for both PM NOx