Downloads

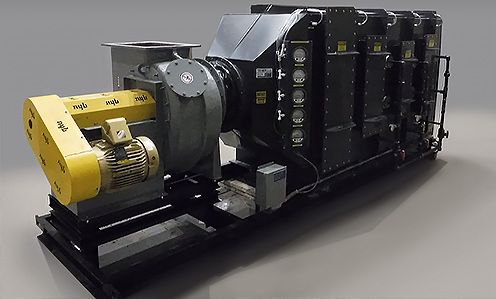

DownloadsThe C/E-1 Chrome Scrubber is a low energy system which generates less than 8" of internal static pressure. Average water consumption for a 20,000 cfm unit is just 15 gpm.

C/E has no internal moving parts to wear or replace, and chrome can be recovered from both the gas stream and the filter.

The standard C/E-1 is Type I Grade 1 gray PVC, the material recommended for high chrome applications. The estimated minimum service life of a filter is 5 years under continuous use.

Standard purchased components furnished on Tri-Mer Corporation Wet Scrubbers are as follows: