Case Studies

Case StudiesBoeing Rotorcraft Systems, known today as the Mobility Division of Boeing Military Aircraft, purchased a Fan / Separator fume scrubber system, also a chrome scrubber and four Crossflow scrubbers from Tri-Mer.

The fume scrubber system is dedicated to handling acid fumes generated by a 5-stage alodize system.

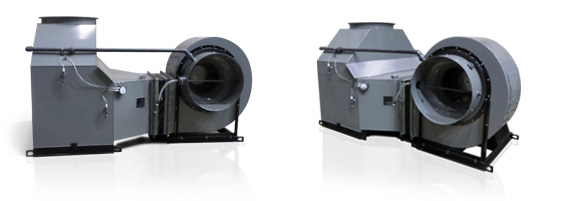

Tri-Mer’s fume scrubber is a highly efficient, double pack system. It is “all-mechanical,” and operates with 20% less brake horsepower than competitive systems. Fan / Separators scrub corrosive fumes at 1/10th the water required by traditional wet scrubbers.

Operational efficiencies are in the 99% efficiency range, thanks in part to use of the fan as a centrifuge in scrubbing. The system is positively pressured, so air is pushed, rather than pulled, through the system. Energy use is typically 15 to 20% less than comparable wet scrubbers that have a negative pressure design.

The Fan /Separator is extremely effective in eliminating corrosive fumes, even when loading is high or variable. It yields a low humidity stack.

Tri-Mer also provided air pollution control systems for finishing lines at Boeing Precision Gear. There, four lines perform eleven different finishing processes: hard chrome, cadmium, copper, nickel, tin and aluminum chromate; also stainless passivation, black oxidizing, pickling, magnesium dichromate and Nital etch.