Surrette Battery Company replaces baghouse with Whirl Wet Dust Collector.

Surrette Battery Company Limited, Springhill, Nova Scotia is a leading lead-acid battery manufacturer, and Canada’s only independent battery manufacturer. The battery company manufactures long-life, true “deep cycle” battery systems for railroad, marine, industrial and renewable energy applications.

Surrette Battery wanted a corrosion-free system that would withstand acid fumes from a paste mixer when materials were damp, and collect the dusts that were generated when materials (which had high concentrations of lead oxide) were dry.

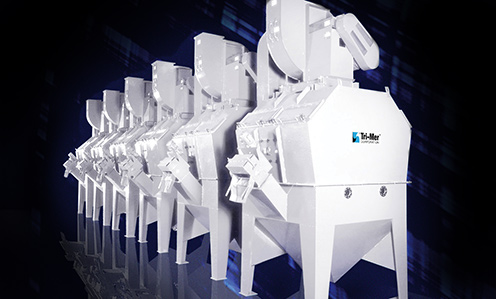

A baghouse met environmental requirements, but the company’s proactive management wanted a more reliable dust collector that had minimal maintenance requirements and would accommodate future growth. The answer was an all-polypropylene Whirl Wet dust collector.

Whirl Wet dust collector systems are widely used throughout the battery industry for collecting lead oxide dusts in battery paste-making operations. These wet dust collector systems operate quietly, accommodate heavy dust loadings and are self-cleaning. Whirl Wet dust collectors can provide for continuous, “24/7” operation.

The 2500 cfm Whirl Wet dust collector chosen by Surrette Battery collects dusts 1 micron and above at 99.5% efficiency. These dust collector systems will not clog or blind in high-humidity conditions, and are unaffected by acid fumes. Water use is low, and water level is maintained automatically.

For abatement of sulfuric acid fume, see our fume scrubbers