This project was for a major manufacturer of a tableted OTC analgesic. The manufacturing process was being redesigned, and a critical aspect of the work was the re-engineering of a reactor.

The client’s original process, which used nitric acid to dissolve a metal, exhausted virtually 100% nitrogen oxide (NO), a gas that reacts with oxygen to form a brown plume at concentrations as low as 50-125 ppm, depending on stack diameter.

The original environmental control device was “grand-fathered” under the Clean Air Act. The redesigned process would require the meeting of new, more stringent regulations.

The requirement was to identify a proven system that used Best Available Control Technologies (BACT) for NOx.

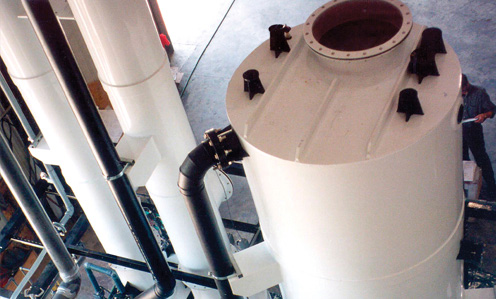

Tri-Mer’s NOx scrubber technology was selected as the foundation for a solution. “Tri-NOx,” Tri-Mer’s NOx system tradename, can be engineered to achieve virtually any concentration level at the stack, and any incoming NO/NO2 ratio. In contrast to SCR (selective catalytic reduction) devices, Tri-NOx is not vulnerable to catalyst plugging, and will accommodate ambient temperature gas streams.

The standard Tri-NOx NOx Scrubber employs a proprietary oxidizing compound, plus dilute sulfuric acid in the first stage. The client preferred not to add these to their chemical inventory, so this application uses air oxidation of NO gas in the first stage to achieve a target NO/NO2 ratio for treatment in the second stage.

A combination of studies and published research indicated that if gas flows were not massive, the Tri-NOx could use air oxidation as an effective first stage. A design was developed that would convert sufficient NO to NO2. Process simulations indicated that chemical savings alone would exceed $100,000 per year.

The client approved the preliminary concept and detail-engineering was completed. Tri-Mer manufactured the equipment and the system was installed and commissioned. Start-up was uneventful and met client and regulatory requirements.

Combining proven BACT system concepts with innovations tailored to the client’s process produced an answer that was effective and cost-efficient. The investment the process evaluation, and subsequent engineering, produced direct cost savings of $1,000,000 over ten years.