Your Questions re: Dust Collection

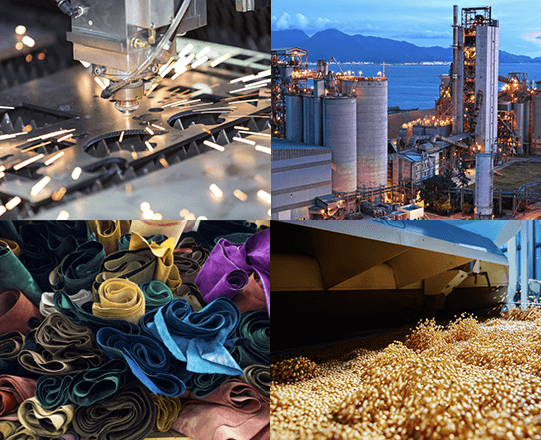

Industrial dust collection includes every type of particulate: coarse and fine (and often both); soluble and insoluble; acid and alkaline; high and low velocities; abrasive; corrosive, hot and cold. Here’s a sample of what companies ask us in an average week.

Q. We are expanding production and want to replace a baghouse with equipment that gives us greater flexibility and if possible, doesn’t require the maintenance – or replacement parts – of this bag house. We’ll have several processes emitting particulate – and the particulate size is variable. It would be ideal to duct every one of these processes to one system. Do you have a solution for this?

A. Wet dust collection systems have several advantages over a baghouse, most notably, there are no filters to replace, or bags to maintain. Tri-Mer’s Whirl/Wet has no internal moving parts and does not use pumps, filters or nozzles. Wastewater is minimal and directly proportional to particulate loading. The Whirl/Wet can accept exhaust from multiple sources. It accommodates high particulate loading, both soluble and insoluble particulate, and particulate of varying sizes. Standard systems are manufactured up to 50,000 acfm.

Q. Can Tri-Mer help specify an exhaust system with wet dust collection capability for our shot-blasting operation?

A. Tri-Mer has extensive experience and design capabilities in implementing exhaust collection systems to capture, convey, and treat particulate matter from shot-blasting applications. We’d be glad to assist in designing a system tailored to your needs and budget.

Q. I am looking for dust collection equipment for the waste that remains in the air when grinding cow feed forage. I want to reuse the removed material; can you help?

A. Reclaim of particulate matter following collection in a wet collector is typically impractical for applications such as this. Dry dust collectors may be a better alternative.

Q. We need to remove dust from the loading of clay and iron oxides. The process generates heat, driving off moisture and causing the dry dust collector to clog. Do you have a solution?

A. Wet dust collection systems are a solid alternative for applications such as this, where particulate matter causes a costly, ongoing maintenance issue for dry filters. Dusts that are hydroscopic and/or agglomerative are ideal applications for wet collection technologies such as the Tri-Mer Whirl/Wet. In addition to its high collection efficiency, has no internal moving parts, filters, nozzles, or pumps to clog under high loading conditions.

Q. We’ll be using a shot blast machine and collecting using our Whirl Wet system. Is an argon fire suppression system needed, since we will be collecting titanium dust?

A. NFPA regulations require fire suppression, explosion vents, and isolation valves for dry collectors, since they have an inherent combustion risk. Your Whirl/Wet dust collector is exempt from these regulations; in addition, the hydrogen release ports on the Whirl/Wet prevent build-up of titanium, magnesium and aluminum and other exotic metals within the collector. Upstream and downstream exhaust systems are a separate concern, so be sure to consult with the appropriate regulatory agencies in your jurisdiction.

This form is the fastest way to get in touch with us.

A more detailed form, located here, will tell us what we need to generate a detailed quote based on your facility needs and culture.