Cement Kiln Exhaust Scrubber

Proven Alternative to Baghouses, ESPs, SCRs

It achieves high reductions of NOx, SO2 and PM when inlet temperatures are high. Its high performance and low life cycle costs are making it increasingly affordable.

Ceramic filtration technology originated from the need to pair the PM removal capability of a fabric filter with the energy efficiency of an ESP.

Like fabric (bag) filters, ceramic filtration works on the concept of barrier filtration. However, unlike fabrics, ceramic fibers form a rigid filter wall, allowing the filter to accumulate and maintain a robust residual layer, even during pulse cleaning. This characteristic permanently moves the barrier filtration zone into the filter cake, preventing penetration of particulate into the filter wall.

The design of the Tri-Mer UltraCat ceramic catalytic filtration system enables reduction of PM10 and PM2.5 to >99.99% levels. The system’s proprietary catalyst is fully protected against plugging or poisoning, ensuring high catalyst integrity for the life of the ceramic filter, and minimizing costs associated with catalyst regeneration.

The development of filter elements 20' and longer has made UltraCat even more cost efficient for cement kiln exhaust and other large gas volumes. The longer filter element also helps with enclosure design, minimizing the footprint where space is at a premium.

Since clinkers are cooled, using ceramic filters at higher temperature can eliminate the need for an air cooler and its attendant power expense. The bag filter in the kiln main exhaust is a second location for raw material recovery where ceramic filtration offers added benefit.

Depending on the raw material, the potential to release organic trace compounds when heated is high. Most of these trace compounds are classified as organic hazardous air pollutants (O-HAPs), primarily aldehydes and aromatics.

The embedded catalyst within the ceramic filter wall can reduce the O-HAPs emission by 90% without further fuel consumption.

Read our article: Reasons to Embrace “Next-Level” Control of Cement Air Emissions Using Ceramic Filtration

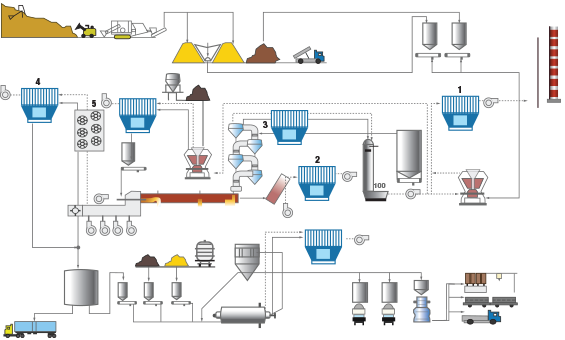

Cement plant with typical installation location for dust separation equipment

The ceramic filtration system can be:

- Added upstream of the exhaust gas cooler, maintaining the existing bag filter just upstream of the stack (position 3) for dust emission control. This design has been realized in a US application.

or

- Retrofitted within an existing baghouse, replacing the bag filter upstream of the stack (position 1) for integrated O-HAPs and dust emission control.

This form is the fastest way to get in touch with us.

A more detailed form, located here, will tell us what we need to generate a detailed quote.