Combustible Dust Hazards

What is combustible dust?

Combustible dust is one of industry's most formidable hazards. Any combustible material suspended in air in the right concentration, and under the right conditions, can ignite and explode. Even stable metals such as aluminum and titanium can spontaneously combust in dust form. Interestingly, now-common technologies such as additive manufacturing and 3D printing also pose combustible dust hazards.

Tri-Mer has proven dust collector technologies that prevent primary combustion events and the secondary (and often more damaging) secondary events that can follow. Specified for new facilities, or those undergoing renovation or expansion, they can save the owner substantial dollars compared to baghouses, which are a common – and widely misunderstood - alternative.

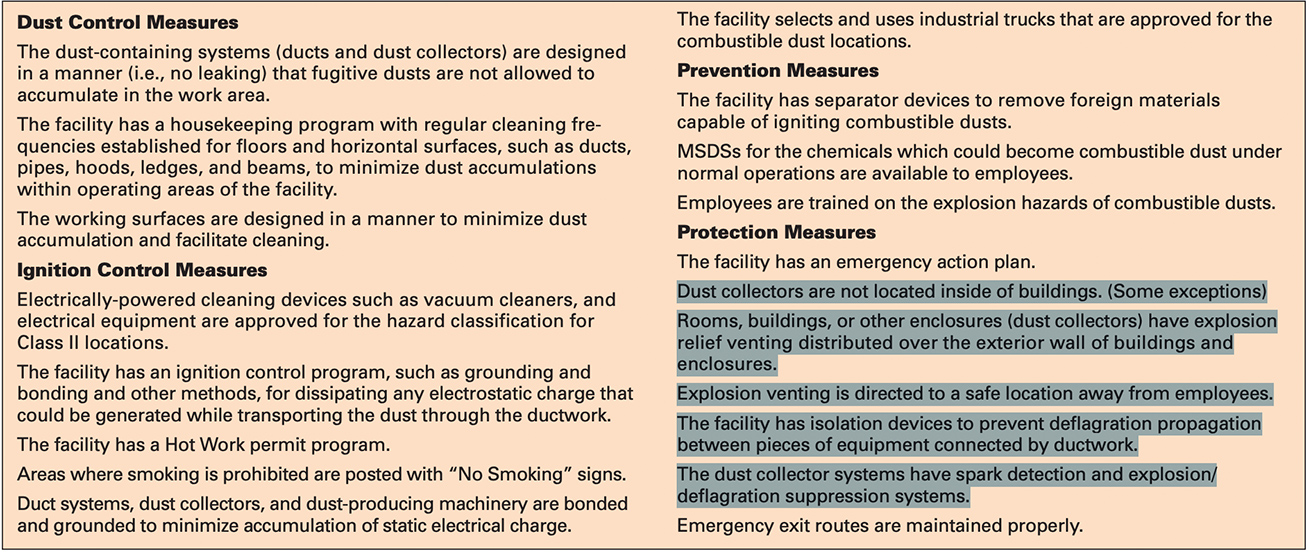

Briefly, baghouses used in the presence of combustible dusts are problematic on several counts. Buildings or enclosures must have explosion relief venting over exterior walls. Specialized fire protection, ember detection systems and deflagration isolation must be part of the installation, along with a means to control static electricity.

During operation, a rise in humidity can quickly create a clogged condition and halt airflow.

When particles are all or partially coarse, they abrade and shorten the life of filter bags. When bags need to be replaced, dust collection (and usually production) stops. The replacement process itself creates dust clouds that necessitate protective gear for workers. The flow-back that occurs during bag replacement means ductwork generally has to be sealed-off to prevent dust from migrating into electrical zones, where ignition potential is highest.

For these and other reasons, wet dust collection has grown in popularity among facility owners, production managers and maintenance foremen. They are also favored by those responsible for asset protection and liability.

Tri-Mer’s Whirl/Wet dust collector, and Whirl/Wet 24/7 continuous operation dust collector are “workhorse” dust collectors, proven performers for the efficient, reliable collection of soluble and insoluble dusts from industrial sources: OSHA list of Combustible Dusts

Whirl/Wet systems have no internal moving parts, do not use “replacement parts” such as bags, filters or pumps, and are highly efficient in their water and utility use. They have a track record in virtually every sector of industry, and a typical service life of 30+ years. More information is here.

This form is the fastest way to get in touch with us.

A more detailed form, located here, will tell us what we need to generate a detailed quote.