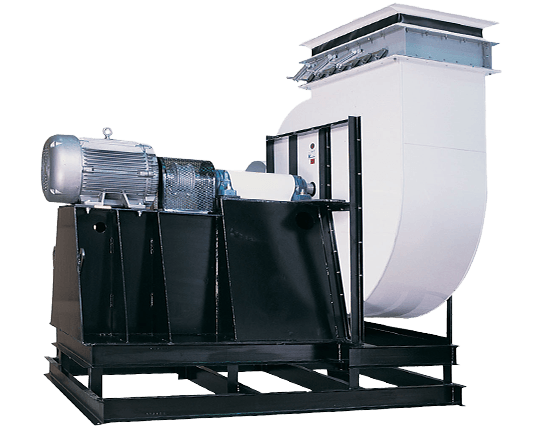

Industrial Blowers: Standard and Custom

Tri-Mer industrial blowers have a well-deserved reputation for high reliability under punishing conditions. Sold alone, or as a core component of an air pollution control system, our experience with exhaust fans goes back to the founding of Tri-Mer Corporation.

The first Tri-Mer equipment brought to market in the early 1960s was the Fan/Separator: a positive-pressure wet scrubber using an exhaust fan as a centrifuge for abatement of acids and alkalis.

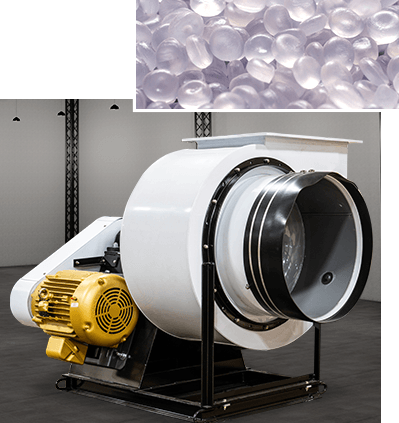

Fan/Separator technology is still widely used for wet scrubbing applications due to its high efficiency and low pressure drop.

Tri-Mer thermoplastic blowers, now advanced to meet the needs of industry, are commonly used to induce gas flow through Tri-Mer’s various wet scrubber product lines.

Features & Benefits

Low noise

for better workplace ergonomics

Low vibration

for better service life

Polypro construction

for long-term durability

Configurations

Tri-Mer industrial blowers are generally belt driven (direct drive arrangements are available); standard blowers have arrangement 9 or 1 configurations; custom configurations are available. These exhaust blowers are standard on Tri-Mer scrubbers.

Tri-Mer exhaust blowers are tested at multiple points during manufacture for material, structural and weld integrity; they are subjected to wheel balance, leakage, noise, vibration and overspeed testing as well. Each blower is also evaluated to determine peak efficiency, and overall efficiency (air power divided by fan input power.)

Tri-Mer industrial blowers operate at up to 180°F. Capacities range from 50 to 150,000 acfm.

Materials

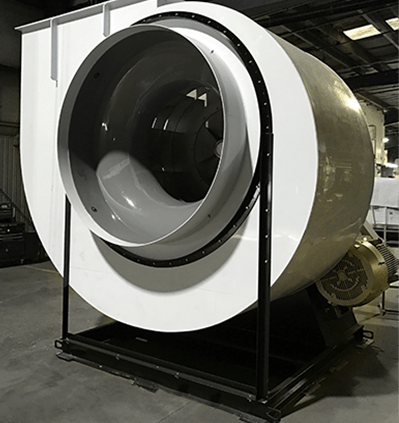

Standard Tri-Mer blowers have a robust polypropylene housing. “Polypro” has the highest abrasion resistance of any thermoplastic. Internal and external support members are also fabricated from polypropylene.

Polypropylene is a homogeneous material and stabilized throughout. This allows for structural integrity and chemical resistance even if the surface of the material is compromised (versus a laminated-resin structure, such as FRP). Polypropylene has excellent impact resistance and chemical resistance to acids and alkalis. Polypro has the longest service life of any thermoplastic.

Optional materials include PVC, fiberglass, 304 and 316L stainless steel, and mild steel.

Manufacturing

Tri-Mer Exhaust Blowers use backward inclined impellers in various materials of construction depending on the application specifics. Tri-Mer’s decades of experience in the design and fabrication of polypropylene equipment and exhaust fan ensures continuous, reliable performance.

All manufacturing is done at our Owosso, Michigan manufacturing campus.

Applications

Tri-Mer supplies blowers, also, scrubbers, process hoods and ductwork, and mist eliminators, to nearly every sector of industry. Tri-Mer blowers are used throughout the chemical process industries, and in the food/beverage, powergen, construction, waste treatment, mining and metal finishing industries.

Tri-Mer blowers are widely specified where applications require robust chemical resistance, high performance, and durability.

This form is the fastest way to get in touch with us.

A more detailed form, located here, will tell us what we need to generate a detailed quote.