Industrial Wet Scrubber

Crossflow Industrial Scrubber

Tri-Mer's Crossflow removes gases and fumes, maintaining stack emissions to specified ppm limits for all input concentrations. The system is capable of handling heavy input loading intermittently, or continuously.

Tri-Mer Corp. guarantees your operating permit level for HCl, HNO3, HF, H2SO4, Cl2 and NH3; it is proven effective for the efficient removal of industry's most noxious - and corrosive - air emissions.

Features & Benefits

High reliability

Low pressure drop

Low water use

Low operating cost

Eligible for Routine

System Performance Review

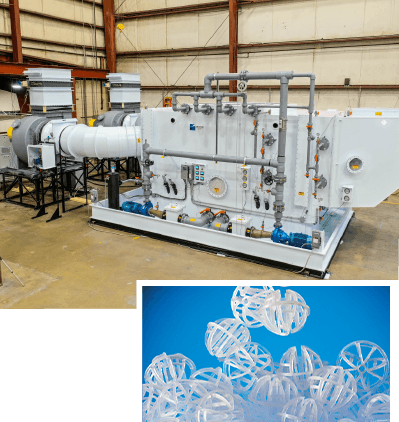

How Our Industrial Crossflow Scrubbers Work

Key to the performance of this system is liquid/gas loading rates that are optimized for the contaminant type and loading.

Tri-Mer industrial scrubbers have two stages. The first stage removes contaminant from the air stream and may be continuously wetted to facilitate mass transfer from liquid to gas phase. Stage two is a mist eliminator. As gases enter the scrubber, a spray header initiates gas/liquid contact. Gases pass through the packing, and mists impinge on the packing. Droplets are rinsed from the bed and soluble gas contaminants are absorbed.

Gases then pass through a mist eliminator, which isolates entrained droplets as clean air is exhausted to atmosphere.

Scrubbing liquid is often recirculated, minimizing the amount of makeup liquid needed as well as the scrubber effluent.

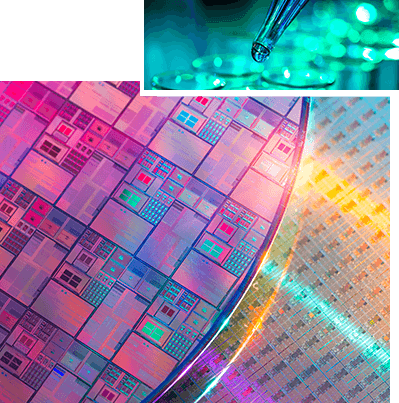

Applications

Applications for the Crossflow include the pharmaceutical, semiconductor, metal finishing, pulp & paper and chemical industries; other facilities generating corrosive fumes and gases, including fertilizer manufacturing and wastewater treatment, also benefit from Crossflow technology.

- Crossflow Industrial scrubbers are often used to remove acid fumes. In these cases, alkali is added to the recycled scrubbing solution to maintain a neutral pH.

- Tri-Mer Corp. will review applications that involve multiple pollutants to optimize scrubber design and identify potential contaminant conflicts.

Materials

Tri-Mer industrial scrubbers are typically fabricated from homogenous, virgin-grade, UV-resistant polypropylene homopolymer, PVC, mild steel or stainless steel. The maximum continuous-duty temperature rating for polypropylene is 180°F; 140°F for PVC.

Tri-Mer's Industrial Wet Scrubber can be equipment with a variety of mist eliminator types depending on the application requirements, from a chevron blade-type (99% efficient on 20 micron and larger droplets) to multi-layer, coalescing type mist eliminators (can achieve efficiencies to 99% at 2 micron and up)

Wet Scrubbers are equipped with random dumped Tri-Pack media.

Have you checked your internals lately?

Tri-Mer’s System Performance Review reports on every aspect of your air emissions system, so it always runs at peak efficiency with NO unscheduled downtime. Learn more here.

This form is the fastest way to get in touch with us.

A more detailed form, located here, will tell us what we need to generate a detailed quote.