Custom Fabrications: All Thermoplastics

Polypropolene, PVC, PVDF Fabrications

Tri-Mer established its credentials in custom fabrication in what was arguably the most precision-driven sector of industry at the time: clean rooms for the manufacture of electronic components.

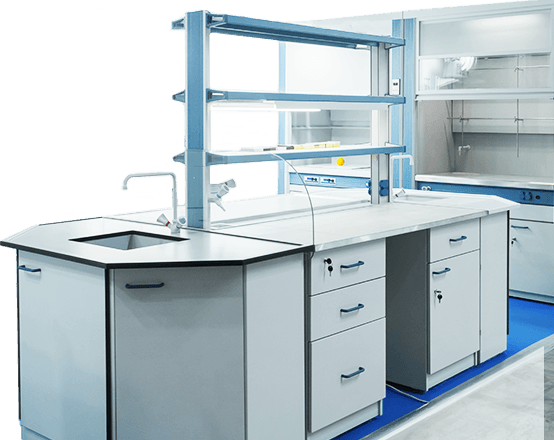

Six decades later, design-building the structural and operational fabrications needed to manufacture components as complex as chips and PCBAs is foundational to Tri-Mer’s mission. We have built a solid clientele for custom-fabricated industrial cabinetry, chemical containment enclosures, and laboratory furnishings, including workstations, hoods, ductwork, process tanks and processing equipment. We also manufacture an all-PVC powder coating booth engineered for low energy use, quick color changes, and ease of cleaning. PVC is the material of choice for powder coat booths.

Experts in Thermoplastics

Tri-Mer’s core business, as you’ve seen on earlier pages of this website, is delivering complete air pollution control systems for a wide range of applications and industries. This core competency, which stretches back to the 1960s, has given us broad, hands-on familiarity and expertise with virtually every industrial thermoplastic material used in industry today.

Most often, our custom fabrication projects use polypropylene copolymer and homopolymer, PVC Type I and II and polyethylene. We also have extensive experience with PVC-C, CPVC, PVDF and FM-approved thermoplastics.

Tri-Mer material specialists and fabrication project managers are experts on chemical compatibility, tensile strength, thermodynamics, and impact strength, as well as the environmental conditions that affect equipment durability.

Techniques Used for Custom Fabrication

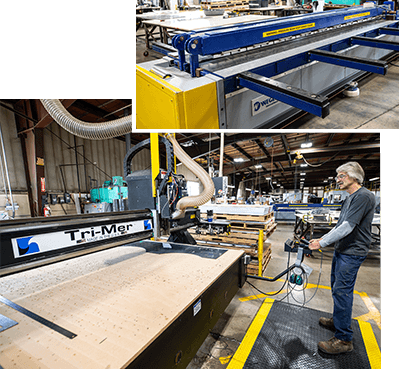

- A CNC router with 1,800 IPM cut speed, 3,000 IPM rapid traverse, scribe layout lines, archived cut files and repeatability of 1/1000th of an inch.

- A corner butt welder that generates precise, homogeneous application of pressure in the weld seam area

- Thermoforming equipment for vacuum formed ductwork

- Extrusion welding with 2000W drive, 5kg weld capacity and ability to weld sheet thicknesses to 30mm

Our fabrication projects often include extreme tolerances, intricate structural engineering, complex geometries, and short lead times. We are comfortable with all of these limitations, and welcome the opportunity to work with you.

Whether you need a prototype build, a seasonal run or continuous production, Tri-Mer has the custom fabrication resources to support your requirements.

We invite you to visit our 300,000 sq. ft. manufacturing campus in central Michigan (it’s the largest custom polypro fabrication facility in the US!) - or contact us using the quick response form below.To generate a detailed quotation, use the form located here.

This form is the fastest way to get in touch with us.