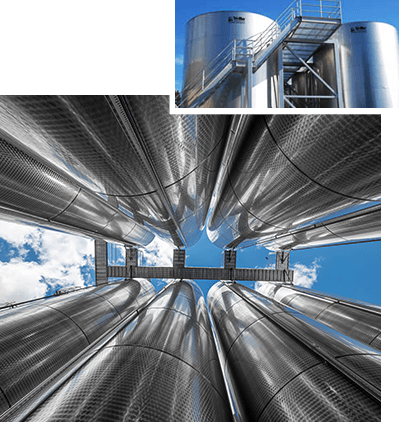

Stainless Steel Process Tanks

Tri-Mer designs, manufactures and installs stainless steel tanks and process vessels in lengths to 110’, depths to 15’.

Stainless steel tanks are fabricated round, elliptical, conical, cylindrical, cone-topped, truncated, or square. Single and double wall tanks, and stackable tanks are also available.

Tanks are manufactured exclusively on our Michigan manufacturing campus and subjected to hydrostatic, liquid penetrant and ultrasonic thickness testing. Radiographic testing is available via established subcontractors where required.

Tri-Mer also supplies stainless steel tank covers, fume hoods, scrubber exhaust systems and blowers, and high-efficiency fume scrubbers.

Features & Benefits

Fully customizable

tank designs

Best option

for corrosives

100% sanitary

interior welds

Best option

for high temperatures

Materials & Design

Tri-Mer manufactures 304 stainless steel and 316 stainless steel tanks; we also fabricate tanks from Inconel, Hastelloy and other elite alloys, and coated carbon steel.

We work with your production and maintenance staffs to design a stainless steel tank to meet your needs for capacity, cost, functionality, and access. Stainless steel tanks are supplied alone, or with material handling, ducting, piping, pumps and agitation, and instrumentation, as well as platforms, guardrails, and catwalks. We provide expert field erection for stainless steel tanks up to 700,000 gallons, throughout the continental US, Canada and Mexico.

Applications

- Food Processing

- Agriculture

- Dairy

- Fermentation

- Chemical Mixing

- Chemical Containment

- Liquid Dispensing

- Reactor Vessels

- Water Storage

- Blowdown Tanks

- Sanitary Tanks

This form is the fastest way to get in touch with us.

A more detailed form, located here, will tell us what we need to generate a detailed quote.