Incinerator Scrubber CISWI, HMIWI, SSI

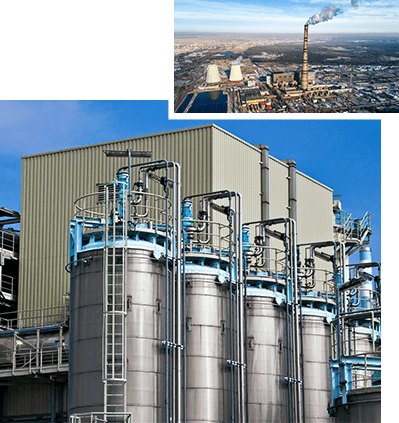

Q-Scrub Incinerator Scrubber

Incinerator exhaust contains a formidable stew of pollutants: inorganic ash particulate, NOx/SOx, SO2, HCl, plus dioxins and heavy metals, most notably lead, cadmium and mercury, the most toxic of the group.

Tri-Mer Q-Scrub offers a field-proven solution for controlling air emissions from high-temperature furnaces and incinerators.

Operating costs are kept low through efficient neutralization of corrosive flue gases, minimal chemical consumption and low pressure drop.

Stack emissions requirements are based on a mass emissions standard of lbs./hr. in vs. lbs./hr. out for contaminants such as HCl, Cl2, SO2, HF, etc.

Features & Benefits

Lowest capital

investment of any wet scrubber

Scrubber

efficiencies of 99% or greater

Systems designed

to guarantee any outlet concentration

Scrubber column

Tri-Packs tower packing media

Eligible for Routine

System Performance Review

How They Work

A multi-stage system is best able to manage the diverse and changeable pollutants, high temperatures, and other conditions inherent in incinerator / WTE applications. Tri-Mer industrial waste incinerator scrubbers are engineered for reliable, continuous operation; low pressure drop keeps operations costs low, while preventing the formation of plumes.

The first stage is a water quench to prevent the re-forming of dioxins from incineration. Q-Scrub systems use proven Tri-Mer Venturi scrubber and packed tower technology as the core stages; carbon adsorption can be be incorporated to treat insoluble organics.

Tri-Mer incinerator scrubbers meet EPA requirements applicable to CISWI (Commercial and Industrial Solid Waste Incineration), HMIWI (Hospital, Medical and Infections Waste Iincinerators), LMWC (Large Municipal Waste Combustors) and SSI (Sewage Sludge Incineration).

Specific applications include

- Rotary kilns

- Calcinators

- Multiple hearth furnaces

- Refractory furnaces

- Fluidized bed furnaces

- Biomass grate furnaces

- Catalytic combustion furnaces

- Waste-fired boilers

- Liquid injection incinerators

- Direct flame gas incinerators

- Hazardous waste incinerators

- Sludge incinerators

- Fume oxidizers

- VOC oxidizers

For projects involving submicron particulate, see CCS - Cloud Chamber Scrubber

Materials

The quench section is constructed of Hastelloy™ C276 and 316L to 304 stainless steels; high-temperature FRP is used for applications below 350°F. The scrubber sections are manufactured in polypropylene, fiberglass or high alloy steel.

Have you checked your internals lately?

Tri-Mer’s System Performance Review reports on every aspect of your air emissions system, so it always runs at peak efficiency with NO unscheduled downtime. Learn more here.

This form is the fastest way to get in touch with us.

A more detailed form, located here, will tell us what we need to generate a detailed quote.