Cloud Chamber Gas Scrubber

Cloud Chamber Gas / Particulate Scrubber

Tri-Mer’s Cloud Chamber scrubber uses charged water droplets to remove particulate (PM2.5, fine, submicron ultrafine and condensable as well as PM10 and coarser particles) at efficiencies of 99% or higher.

Simultaneously, CCS removes all gases that are treatable with a wet scrubber, including HCl, NO2, SO2, Cl2, NH3, HF, H2SO4, HNO3, ammonia and amine compounds. The ability to treat particulate and corrosive fumes simultaneously and efficiently is a prime advantage of CCS technology.

Features & Benefits

Accomodates

high loadings

Not sensitive

to load flux

Low

operating cost

Eligible for Routine

System Performance Review

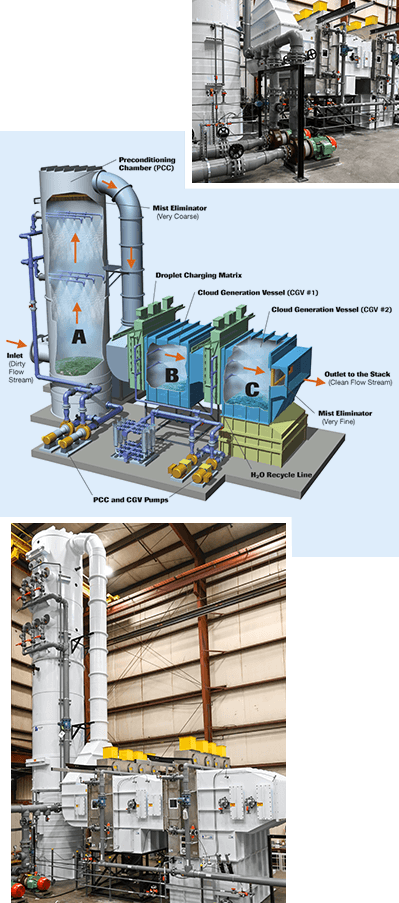

How the Cloud Chamber Gas Scrubber / Particulate Scrubber Works

Cloud Chamber Scrubber works by passing an incoming gas stream through a scrubbing cloud of dense, charged water droplets. Inside the wet scrubber, billions of charged droplets interact with the particles. When a particle and droplet pass within 20 microns, the droplet charge induces a dipole force which causes the particle to be pulled into the droplet, making each water droplet a particle collector.

Droplets collect particles as they interact with the gas stream, and are washed into the sump. Captured particles agglomerate, settle, and are removed as a low volume slurry. Clean water from the top of the sump is re-circulated to the preconditioning chamber (PCC), where it is recharged, completing the cycle.

The Cloud Chamber Scrubber has three zones: preconditioning chamber (A) for removal of coarse particles and humidity-temperature adjustment; cloud generation vessel (B) for removal of neutral and negative submicron particles, and a second cloud generation vessel (C) with negatively charged droplets to capture neutral and positive particles. Treated air flows through a mist eliminator prior to discharge.

Just 10 watts per 1000 cfm are required to charge the water droplets, plus moderate pump power for recirculation. Maintenance costs are also low: Cloud Chamber uses minimal water, and generates less than 1.5” w.g. pressure drop across the system.

Cloud Chamber gas / particulate scrubber accommodates loadings as high as 2,000 mg/m3, reducing mass emissions to below 5 mg/m3. Its performance is superior to high-energy venturis, diffusion candles and ESPs. It is a practical engineering solution as a stand-alone unit, or as a tail gas scrubber for existing equipment.

| Best Available Control Technology for Submicron Particulate | |||||

|---|---|---|---|---|---|

| CCS® | Wet Packed Bed | Venturi | Baghouse | Wet ESP | |

| Meets PM2.5 | ✓ | ||||

| Captures <3.0 micron @ +98% | ✓ | ✓ | ✓ | ✓ | |

| Captures <1.0 micron @ +98% | ✓ | ✓ | |||

| Captures Fumes/Gases (HCl, Cl2, HF etc.) | ✓ | ✓ | |||

| PCM Field Array Power Requirement less than 600 watts, regardless of cfm | ✓ | ||||

| Pressure Drop < 1.0" H2O per stage | ✓ | ||||

Applications

- Diesel from ships at port

- Diesel engine test cells

- Diesel locomotive engines

- Large stationary diesel equipment

- Refineries

- Glass furnace emissions

- Solar panel manufacturing

- Abrasives production

- Chemical manufacturing

- Plastics manufacturing

- Biofuels production

- Sulfuric and nitric acid production

- Wet electrostatic precipitator replacement

Have you checked your internals lately?

Tri-Mer’s System Performance Review reports on every aspect of your air emissions system, so it always runs at peak efficiency with NO unscheduled downtime. Learn more here.

This form is the fastest way to get in touch with us.

A more detailed form, located here, will tell us what we need to generate a detailed quote.