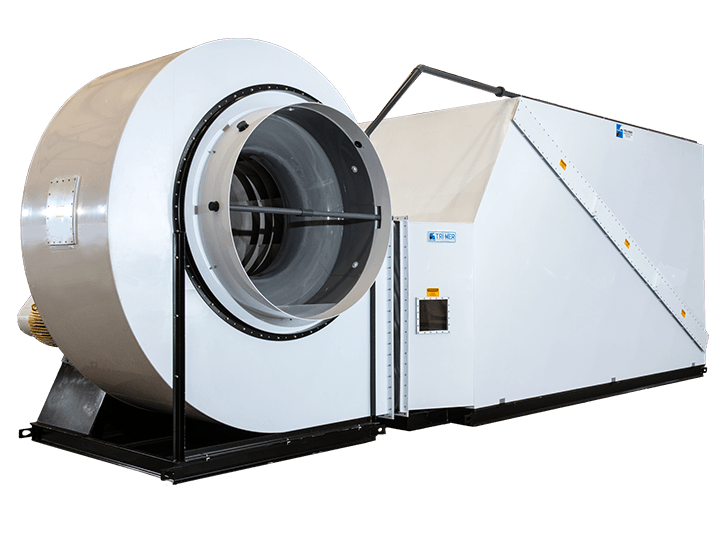

Fume and Mist Eliminator

Fan/Separator Controls Toxic Air Pollutants

Included are H2SO4, heavy metals, VOCs and other fumes generated from steel pickling, plating, anodizing and other common industrial processes. Fumes from battery charging can be eliminated more efficiently, and with less water and energy using Tri-Mer's Fan/Separator - a huge benefit for this important growth market.

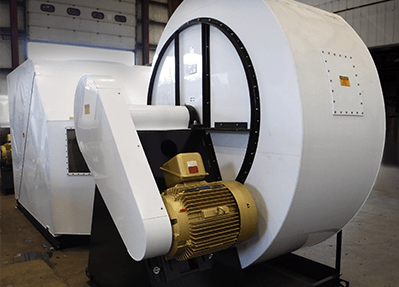

Fan/Separator scrubber sections and fans are manufactured in tandem to prevent fan under-sizing, an issue that is often under-appreciated until it affects performance. Fan outlet velocity is precisely controlled, so air crossing the rigid packed media stays comfortably within design parameters. The system is positively pressured, working the reverse of conventional "negative air" scrubbers. Thus, air is pushed, rather than pulled, through the system.

The Fan/Separator is exceptionally efficient in eliminating corrosive contaminants while producing a low humidity exhaust stack. This combination of low humidity and separation perfomance makes return air possible in many applications - another plus for facility cost management.

Tri-Mer's Fan/Separators operate in the 99% efficiency range, using less than 1/10 the water of traditional wet scrubbers made for this purpose. They also require 20% less brake horsepower due to a unique design that incorporates the fan as a centrifuge in the scrubbing process.

Features & Benefits

Low

water use

Compatible with

high flow velocities

No-loss Stack

maximizes energy efficiency

Eligible for Routine

System Performance Review

How It Works

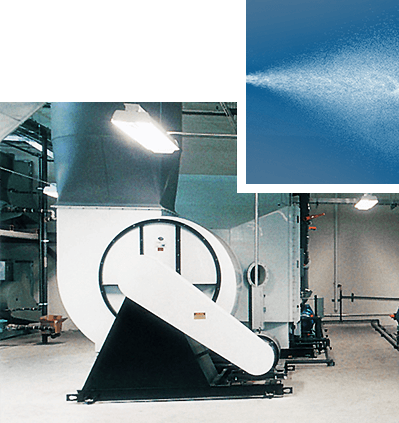

Tri-Mer's Fan / Separator is an all-mechanical, dual-stage fume scrubber. A fog mist of scrubbing liquor wets the fume as it enters the fan, allowing it to be centrifugally spun out of the fan scroll through dynamic mixing. The centrifugal action, using the fan wheel as part of the scrubbing process, eliminates approximately 55% of airstream contaminants.

The impingement process that follows causes the air to change direction as it passes across the packing media. The media also functions as a mist eliminator, and delivers 99% removal efficiency of 20 micron and larger liquid droplets under continuous duty loading.

Operation

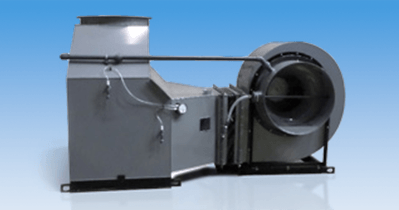

55% of system performance results from contact between the contaminant-laden air and the rigid tube packing; 45% is from the centrifugal action of the fan wheel. The unit is extremely effective in eliminating corrosive contaminants; outlet air approaches saturation. Total energy consumption is typically 15 to 20% less than comparable wet scrubbers that have a negative pressure design.

Materials and Specifications

Single Fan/Separator units are manufactured in capacities to 100,000 cfm. Systems are engineered for simple installation and commissioning, minimizing start-up costs.

UV-stabilized PVC or polypropylene are standard material options; 304 and 316L stainless steel and mild steel are also available.

Tri-Mer Corporation also manufactures duct systems in these materials, as well as tanks, fume hoods, and custom fabrications for manufacturing and laboratory environments.

Have you checked your internals lately?

Tri-Mer’s System Performance Review reports on every aspect of your air emissions system, so it always runs at peak efficiency with NO unscheduled downtime. Learn more here.

This form is the fastest way to get in touch with us.

A more detailed form, located here, will tell us what we need to generate a detailed quote.