High Temperature Filter Technology

UltraCat High Temperature Filtration

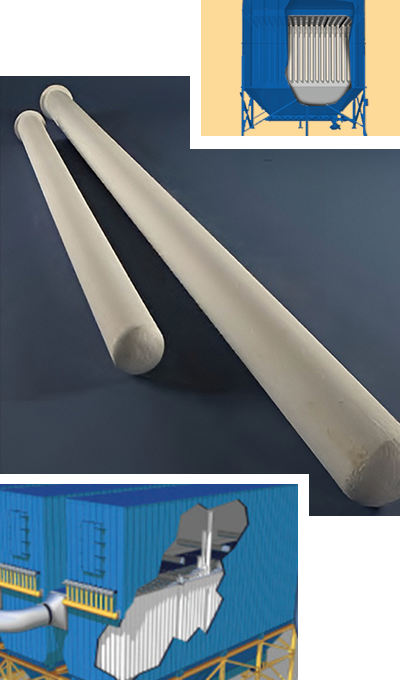

Ceramic filters have been a staple of air pollution control for decades. Ceramic filters were originally manufactured from refractory grains such as alumina and pressed into a candle shape – a tube with a closed, rounded bottom and a flanged top.

The high temperature filters used in the UltraCat are very different in their design, service life, and multi-pollutant functionality. They are also robust, and self-supporting without filter cages. Tri-Mer filters control SO2, HCl, NOx and particulate (PM) in a single highly efficient system, and can be adapted to handle mercury and dioxins as well.

Features & Benefits

90%

NOx reduction

PM

reduced to ultralow levels

90%+

removal of acid gases

How they work

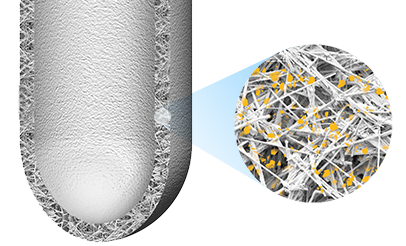

Tri-Mer high temperature filters start as a slurry of refractory fibers and are vacuum formed into shape. They are very lightweight, approximately 90% open, with much lower pressure drop.

Characteristics

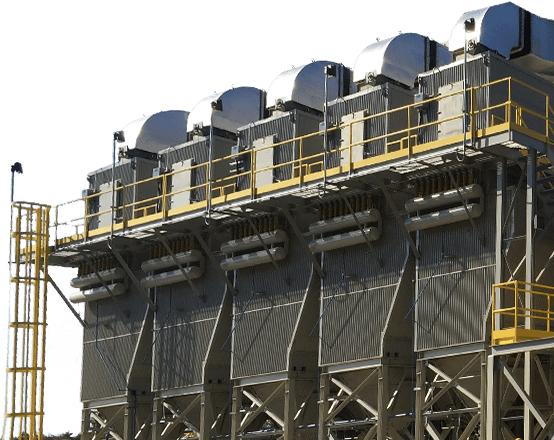

Filters are manufactured in various lengths; the 3-meter (10-ft.) filters have been in highest demand by industry. The filters are placed in a housing similar to a baghouse.

Tri-Mer high temperature filters are chemically inert and corrosion-resistant, as would be expected from ceramic materials. Filters are manufactured in two varieties:

- standard non-catalyst ceramic filters

- ceramic catalyst filters

Tri-Mer’s catalyst filter is identical to the standard filter, except that it has nano-bits of SCR catalyst embedded in the filter walls for NOx removal, Organic HAPs, CO, and dioxin destruction.

The catalyst particles in ceramic catalyst filters are micro-porous, and due to their small size, they catalyze the gas phase reactions without diffusion and restriction (i.e. nearly 100% utilization of the catalyst's intrinsic activity). This is an important advantage, and in stark contrast to pellet or monolithic catalysts. In industrial environments, conventional catalyst types typically operate with 5-15% catalyst effectiveness in the SCR (Selective Catalytic Reduction of NOx by NH3).

Replacement ceramic filters are a quick phone call (rather than a months-long boat ride) away. FLKCAT ceramic filters, exclusively from Tri-Mer Corp. are robust and self-supporting. They simultaneously control SO2, HCl, NOx and particulate, and can be adapted to handle mercury and dioxins as well. Learn more

Tri-Mer is the stocking distributor for ceramic filters in all common dimensions.

This form is the fastest way to get in touch with us.

A more detailed form, located here, will tell us what we need to generate a detailed quote.