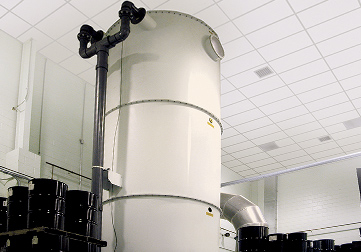

Packed Bed Industrial Scrubber

Packed Bed Scrubbers

These versatile, reliable wet scrubber systems serve the widest variety of processes, at a capital cost lower than conventional alternatives. They efficiently remove inorganic gases, odors, fumes and water-soluble organic compounds, including Cl2, HCI, HCN, HF, H2S, NH3, NOx, and SO2.

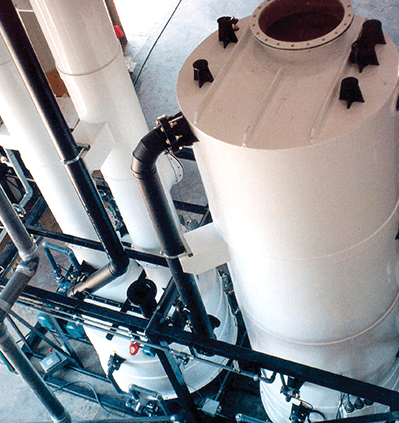

Tri-Mer packed bed scrubbers perform well as primary or secondary systems in conjunction with thermal oxidizers, and are used in series for multiple-contaminant gas streams. Systems can be engineered to include particulate removal, as well as gas quench sections for high inlet temperatures. Where gases have low solubility, scrubbers are designed with extra depth packed beds, and secondary chemical treatment.

Every installation is different in terms of pollutant mix, concentration, temperature and emissions targets, but Tri-Mer packed bed scrubbers typically achieve continuous scrubbing efficiencies above 98%.

Features & Benefits

Capacities

to 100,000+ cfm

Widely specified

for high pollutant concentrations

Small

footprint

Tri-Packs

tower media

Eligible for Routine

System Performance Review

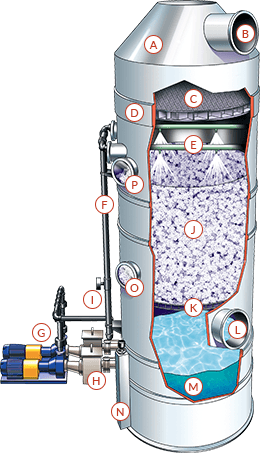

V/F Configuration

Packed bed scrubbers’ vertical format allows gas to flow counter-current to liquid flow.

Packed scrubbers have a smaller footprint in exchange for increased height. They’re generally less costly from both capital and operational perspectives.

|

Scrubber body |

|

Outlet from the scrubber |

|

Mist eliminator |

|

Mist eliminator access door |

|

Recirculation liquid distribution nozzle system |

|

Recirculation piping system |

|

Recirculation pumps |

|

(Optional) recirculation system basket strainer |

|

Liquid flow meter |

|

Packing media: Tri-Packs |

|

Packing support grid |

|

Scrubber inlet |

|

Recirculation tank |

|

Recirculation sump level control system |

|

Packing removal portal |

|

Packing fill door |

How They Work

Inlet air is introduced at the scrubber’s lower section, and travels upward through the packed bed, where it encounters scrubbing liquid. The liquid coats the packing, forming a thin film and neutralizing the contaminants. Moisture droplets are removed via a mist eliminator and scrubbing liquor is recycled. Clean air is discharged to atmosphere or returned to the process.

All Tri-Mer systems are custom-designed to the specific application. Gas stream profile data - including flow rate, temperature, contaminant loading/concentration, and efficiency requirements - are all key variables which direct the scrubber design.

Applications

Packed bed scrubbers are suitable for food and pharmaceutical processing, chem/petrochem facilities, metal finishing, electronics and semiconductor fabrication, pulp & papermaking, hazardous waste management, wastewater treatment and biomass/WTE facilities requiring high efficiency.

Tri-Mer packed beds are also highly suitable for calcining and incineration, for emergency activation and for the venting of chemical storage tank vapors.

Have you checked your internals lately?

Tri-Mer’s System Performance Review reports on every aspect of your air emissions system, so it always runs at peak efficiency with NO unscheduled downtime. Learn more here.

This form is the fastest way to get in touch with us.

A more detailed form, located here, will tell us what we need to generate a detailed quote.