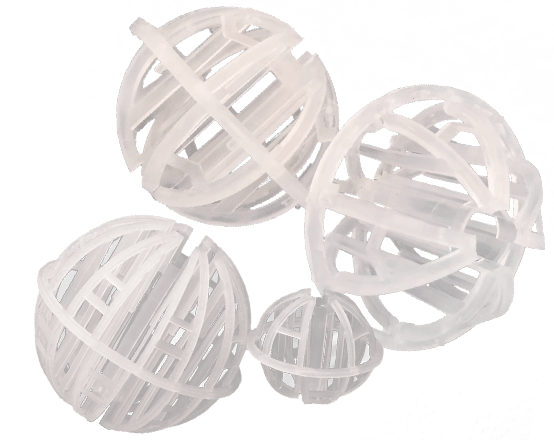

Tri-Packs Tower Packing Media

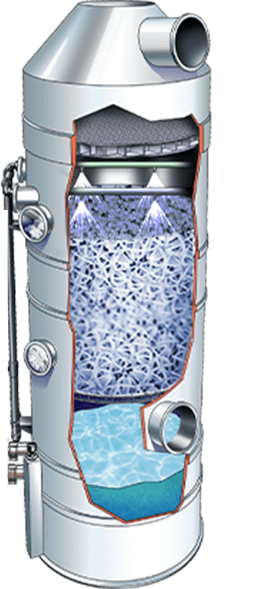

Tri-Packs tower packing, aka random tower packing, tower internals, or scrubber balls, delivers highest performance for a broad range of mass transfer and separation processes. It is widely specified for use in water and air pollution control systems, where a highly active surface area and low pressure drop is desirable.

In scrubber applications, Tri-Packs provides maximum surface contact between the gas and scrubbing liquid by facilitating continuous formation of droplets throughout the packed bed. This maximizes scrubbing efficiency, and minimizes packing depth. Tri-Packs has a high strength to weight ratio, and a high heat transfer coefficient.

Features & Benefits

Superior wetting

due to the distinctive geometries of ribs, struts and drip rods

Reduces clogging

because there are no flat surfaces to harbor particulate

Eliminates puddling

free of corners and valleys; minimizes wasteful liquid flow

Prevents dry spots

as well as compression interlock

Performance

Tri-Packs has a unique spherical shape that has been proven in air pollution control systems for decades. This versatile tower media is also the industry standard for separation, purification and degasification systems, and for tower aeration in applications such as water and wastewater treatment.

Several factors make the Tri-Packs design particularly effective for scrubber applications:

- The media's shape prevents nesting and settling, while creating the optimum surface-to-open-area ratio.

- A distinctive configuration allows Tri-Packs media to maximize wetting, as well as the uniformity of liquid distribution throughout the bed.

- Because there are no flat surfaces, corners or valleys, liquid flow is optimized.

Interestingly, surface area is only one of several factors impacting performance. Too much surface area can impede gas/liquid contact and create higher pressure drops, thus increasing horsepower demand. Tri-Packs has a long history of solid performance in air pollution control applications, benefitting users with high mass transfer and high heat transfer efficiencies, and a proven ability to keep operating costs low.

Tri-Packs tower packing is the industry standard for random dump tower packing media.

Material and Properties

Tri-Packs column packing material is available in four sizes and numerous resins, including polypropylene, glass-filled polypropylene and PVDF.

| Properties of Tri-Packs Tower Packing | ||||

|---|---|---|---|---|

| Size (inches) | 1" | 1-1/4" | 2" | 3-1/2" |

| Geometric Surface Area (ft2 ft3) | 85 | 70 | 48 | 38 |

| Packing Factor I/ft | 28 | 25 | 16 | 12 |

| Void Space % | 90 | 92 | 93 | 95 |

| Weight (lb/ft3) | 6.2 | 5.6 | 4.2 | 3.3 |

Mass Transfer Data of Tri-Packs

| Absorption System | G (lb./hr. ft2) |

L (lb./hr. ft2) |

Temp (F°) |

HTU (inches) 2" & 3-1/2" |

HTU (inches) 1" |

|---|---|---|---|---|---|

| HCl-H2O | 1792 | 2048 | 77 | 10.6 | 7.0 |

| HCl-NaOH | 1567 | 2048 | 68 | 8.8 | 6.1 |

| Cl2-NaOH | 1229 | 2202 | 122 | 14.5 | 9.9 |

| NH3-N2SO4 | 492 | 1024 | 68 | 6.0 | 4.1 |

| NH3-H2O | 512 | 1024 | 68 | 8.4 | 5.6 |

| NH3-H2O | 512 | 4096 | 68 | 5.4 | 3.6 |

| SO2-NaOH | 1946 | 4096 | 140 | 12.0 | 8.1 |

| HF-H2O | 1844 | 3072 | 77 | 6.9 | 4.6 |

| CH2COCH3-H2O | 1700 | 860 | 68 | 15.2 | 10.2 |

| H2S-NaOH | 1229 | 1331 | 68 | 19.4 | 13.0 |

| VOC Stripping | G (lb./hr. ft2) |

L (lb./hr. ft2) |

Temp (F°) |

HTU (inches) 2" & 3-1/2" |

HTU (inches) 1" |

|---|---|---|---|---|---|

| TCE(ppm)-H2O | 479 | 12264 | 77 | 26.9 | 21.5 |

| TCE(ppm/ppb)-H2O | 690 | 12494 | 60 | 37.6 | 30.1 |

| BTX(ppb)-H2O | 722 | 4998 | 70 | 39.2 | 31.4 |

Consult Tri-Mer Corp. for HTU data based on your application

Tri-Packs tower packing is universal in systems manufactured by Tri-Mer Corporation. It is also the preferred tower media for aftermarket requirements, and for systems manufactured by other manufacturers of scrubbers, as well as distillation towers, degasification equipment, ammonia strippers, air strippers, and cooling towers.

Have you checked your internals lately?

Tri-Mer’s System Performance Review reports on every aspect of your air emissions system, so it always runs at peak efficiency with NO unscheduled downtime. Learn more here.

This form is the fastest way to get in touch with us.

A more detailed form, located here, will tell us what we need to generate a detailed quote.