All Mechanical Chrome Scrubber

Chromium is the 17th most abundant element in the Earth’s mantle. But for many OEM’s, it is the #1 air emissions challenge.

Tri-Mer’s C/E-1 is a field-proven chrome scrubber that eliminates fine chrome mist and particulate, including Cr6 and Cr3. Efficiencies are 99.5% or higher, regardless of input loading. Its unique design is all-mechanical, scalable, and has no internal moving parts to wear or replace.

The C/E-1 system does not use chemicals or generate waste. Energy and water consumption are both extraordinarily low; average water consumption for a 20,000 cfm unit is just 15 gpm.

Features & Benefits

Chrome recovery

from gas stream and the filter

Long filter life

10 years to primary maintenance

Low energy use

generates < 6" of wg

Eligible for Routine

System Performance Review

How C/E-1 Chrome Scrubbers Work

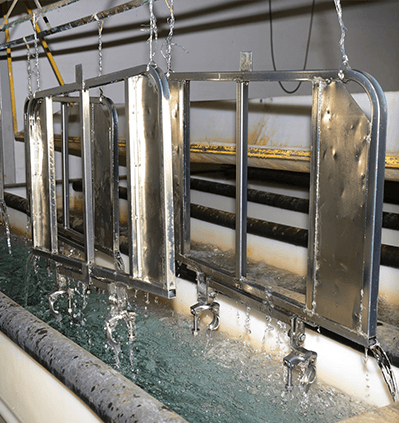

Tri-Mer chrome scrubbers use a multi-layer composite mesh that has proven to be the most effective technology for capturing emissions from chrome plating operations. The filtration system is indefinitely reusable.

This mesh pad system operates under negative pressure and has multiple stages; each stage provides progressively higher efficiency.

The initial stages provide coarse separation and the bulk removal of chromic acid mists; intermediate stages provide 99%+ collection efficiency of droplets down to 1 micron – the performance level required to satisfy the most stringent emission limits.

The filter apparatus is washed continuously in a virtually closed loop. When chrome levels approach the set point (generally 3000 ppm) water is forwarded to chrome recovery or returned to the plating bath.

The outlet concentration achieved is 0.006 mg/m3.

Applications

C/E-1 was engineered for chromic anodizing and plating lines. The system is particularly adept at managing high and variable loading, and is adaptable for the simultaneous scrubbing of fumes containing zinc, silver, platinum, and other materials.

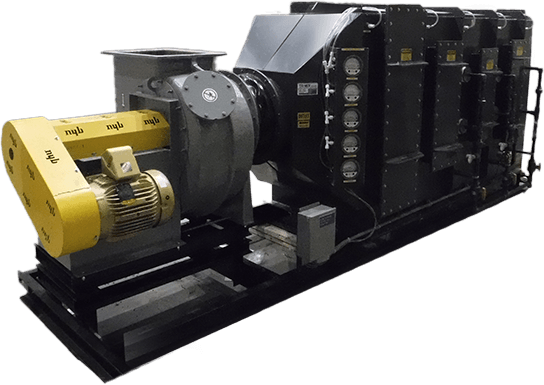

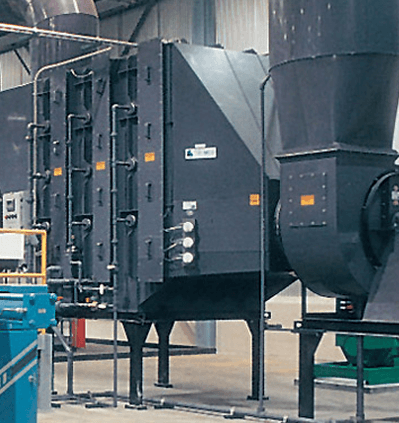

The standard CE/1 chrome scrubber is simple to install available in capacities to 50,000 cfm. Tri-Mer provides a skid-mounted package which includes duct connections, controls interfacing, fan, recirculation tank, pump and piping; installation is by plant personnel, or Tri-Mer field technicians.

Custom chrome scrubbers are available to 100,000 cfm, with field installation.

Materials

The standard C/E-1 housing is Type 1 PVC, the material most recommended for high chrome concentrations. Construction format is modular; horizontal or vertical, and tailored to site requirements.

- Exterior flanges are PVC, angle welded to housing for standard duct hookup.

- Interior flanges are PVC, angle and structural material welded to housing.

- Liquid connections are standard PVC threaded, socket or 150# flanged.

Have you checked your internals lately?

Tri-Mer’s System Performance Review reports on every aspect of your air emissions system, so it always runs at peak efficiency with NO unscheduled downtime. Learn more here.

This form is the fastest way to get in touch with us.

A more detailed form, located here, will tell us what we need to generate a detailed quote.