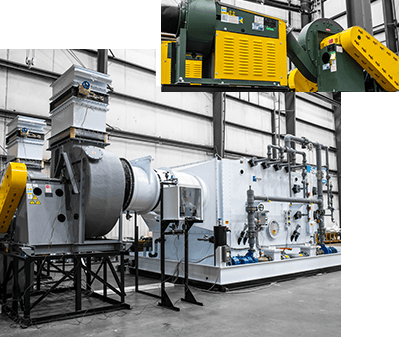

Cartridge-Based Acid Scrubber

UltraScrub Acid Fume Scrubber

Tri-Mer UltraScrub acid gas scrubbers are precision-engineered to the application and provide removal efficiencies of 99% or higher, with low pressure drop.

The scrubber uses Tri-Packs tower media, a mist eliminator, and a liquid distribution system to remove acid gases by a combination of neutralization and absorption.

Features & Benefits

Operates “dry”

99% of the time

Independent gauges

indicates cleaning rqd.

Scrubber design

prevents fan corrosion

Eligible for Routine

System Performance Review

How Acid Scrubbers Work

The first stage is proprietary rigid tube packing, which sacrificially prefilters the air ahead of the scrubber section. There is no visual carryover from stage one forward.

Mists next contact a stage containing 1" Tri-Packs “random-dump” packing. This media prevents the formation of dry spots and compression interlock, two problems common to packing media that cause liquid and air to channel, thereby reducing system efficiency. Tri-Packs develops a very low static pressure per foot of depth, so tower size and scrubbing liquid can be minimized.

The next stage is a dual mist eliminator developed by Tri-Mer for this purpose, which has a minimum performance of 99% on 2 micron droplets. Captured acid mists are expelled with other process wastewaters.

Materials

Where process temperatures are below 180° F, Tri-Mer industrial scrubbers are primarily fabricated from homogenous, UV-resistant polypropylene homopolymer. Systems are also manufactured from PVC, mild steel and stainless steel.

Fans are manufactured from FRP, PVC/PP or stainless steel, or an equally suitable material.

Applications

Tri-Mer acid scrubbers control emissions from SO2, HCl, H2S, and other halogenated compounds which form acid gases during thermal oxidation.Tri-Mer acid scrubbers also control HBr, HCN, and organics such as acetic acid.

- Battery manufacturing and recycling; dry charge formation operations

- Biomass/ WTE

- Fertilizer production

- Pharmaceutical manufacturing

- Chemical processing

- Hot metal foundries

Have you checked your internals lately?

Tri-Mer’s System Performance Review reports on every aspect of your air emissions system, so it always runs at peak efficiency with NO unscheduled downtime. Learn more here.

This form is the fastest way to get in touch with us.

A more detailed form, located here, will tell us what we need to generate a detailed quote.