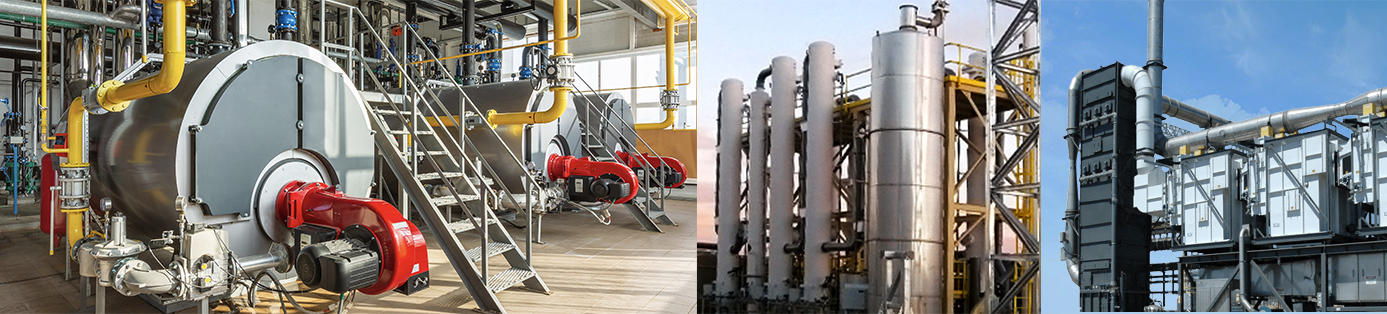

Industrial Boilers, Process Heaters

Tri-Mer UltraCat has become the global gold standard for the efficient control of emissions from coal-fired, biomass-fired, and liquid-fired major source boilers.

UltraCat provides operators of ICI boilers and process heaters with efficient, reliable control of their primary emissions - NOx/SOx and particulate - as well as mercury, HCl, HF. The system provides guaranteed compliance with Boiler MACT, and CISWI MACT, as well as Lime MACT 2, HWC MACT, Cement NESHAP, Title V Compliance, CARB Diesel Regs, EPA Glass Regs and EPA Ceramics Regs.

UltraCat is an all-dry system that accommodates high inlet temperatures (up to 1650°F) and large gas volumes. An auxiliary equipment module simplifies dry sorbent injection where needed.

Boiler operators can often decrease SO2 emissions by re-powering a boiler for solid fuel combustion, or by moving from coal to natural gas. These steps can lower emission levels for SO2, NOx and other contaminants somewhat. When this is insufficient to meet regulatory requirements, or production increases, UltraCat is a proven strategy for substantial, cost-effective and long-term reductions of a broad spectrum of regulated air emissions.

For smaller scale or highest (90%+) NOx reduction, Tri-Mer recommends its Tri-NOx system. Tri-NOx scrubber systems accommodate any ratio of NO and NO2, including combustion-generated NOx, which is highest in NO.

Tri-Mer's NOx scrubber guarantees a clear stack, preventing the plumes that typically result from high NO2 loadings.

For submicron particulate co-mingled with gas pollutants, Tri-Mer offers a 3rd boiler emissions alternative. Tri-Mer's Cloud Chamber uses a “scrubbing cloud” of high-density, charged water droplets that aggressively interact with particulate. Each individual water droplet is effectively a particle collector.

The most notable features of the Cloud Chamber are its low power draw, and the “maintenance parts” that are not used. These include fibrous filters, collector plates, venturi throats, layered pads, bags, and cartridges. This is a major contributor to the very low life cycle cost of this unique scrubber option.

This form is the fastest way to get in touch with us.

A more detailed form, located here, will tell us what we need to generate a detailed quote.