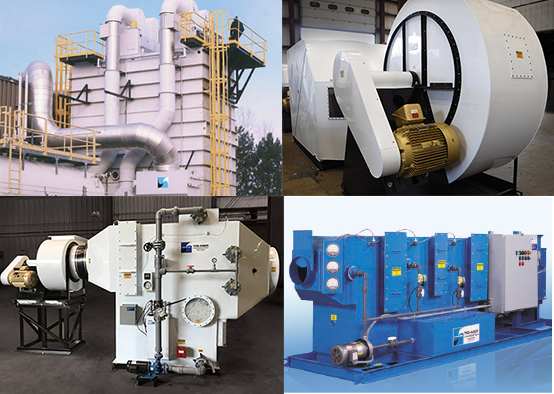

Wet Scrubber Pilot Plants

Tri-Mer has a wet scrubber, and wet and dry dust collectors, for virtually every air emissions issue: dust and submicron particulate, gases, fumes - and multiple-contaminant applications.

When a process is new and complex, site conditions are unique, or a process is still evolving, the most effective solution can be a Tri-Mer pilot plant.

Tri-Mer offers wet scrubber pilot plants in capacities of 1000 to 3600 cfm. Wet scrubber pilot units are “turnkey,” with ducting, fans, pump and piping. They can also include control modules.

The Whirl/Wet scrubber is the most efficient system available for collecting industrial dusts over 5 microns.

It is suitable for both soluble and insoluble dusts, as well as powders and fines, and is ideally suited to the collection of combustible dusts. Water use and energy consumption are both low.

In contrast with other dust collectors, Whirl/Wet has a stellar uptime record, and will not clog under any operating conditions. Also, there are no bags or other high-maintenance items to replace. More than 8000 Whirl/ Wet systems are in operation in North, Central and South America and Europe. There are models suitable to any loading, and a 24/7 option that operates continuously without shutdown.

Tri-Mer has an emergency use program, a flexible rental option, and longer-term wet scrubber leasing plans. All 3 are useful for industrial and university projects that involve feasibility studies, performance testing, or seasonal production.

Tri-Mer will build a pilot unit to suit specific facility requirements for collection/destruction of NOx, SO2, HCl, H2SO4 and dozens of other emissions – and combinations of emissions, including systems to control both gases and particulate. Included are:

Cloud Chamber® Wet Scrubber for Submicron Particulate

- Eliminates particulate down to 0.1 microns.

- 99.99%+ efficient for particulate from 0.1 to 300+ microns.

- Highly effective as a Tail Gas Scrubber CCS.

- Removes fumes and gases, including HCl, HF, HNO3, H2SO4, SO2, Cl2 and NH3, simultaneously with particulate.

- Excellent, lower cost alternative to electrostatic precipitators when particulate is suspended in hot gas streams.

Fan / Separator® Wet Scrubber for Corrosive Fumes

- Best wet scrubber technology available for sulfuric acid fumes, other common corrosives.

- Uses 1/10th the water of other wet scrubber devices.

- All-mechanical wet scrubber operates at 20% less brake horsepower than conventional wet scrubber devices.

- Energy use is 15 to 20% less than comparable wet scrubber devices due to positive pressure design.

- Fan/Separator wet scrubber is field-proven and preferred for sulfuric acid, pickling, metal plating and battery charging.

Crossflow Wet Scrubber Guarantees Your Operating Permit Level Out the Stack

- Best wet scrubber technology available for sulfuric acid fumes.

- Crossflow wet scrubber scrubs virtually all inorganic compounds.

- Maintains stack emissions to specific PPM level for all input concentration.

- Wet scrubber with quench accommodates inlet temperatures to 2000°F.

- Crossflow wet scrubber operates at velocities between 150 and 500 ft./min.

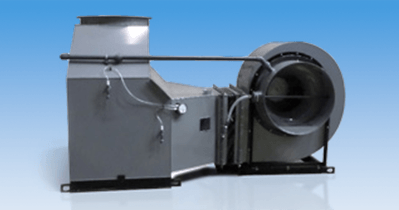

Oil Mist Wet Scrubber for Neat Cutting Oils and Water-miscible Cutting Fluids

- Wet scrubber accommodates multiple oil mist sources.

- Meets latest standards for oil mist exposure.

- Cleans the air, reduces housekeeping, lowers combustion risks.

- Low pressure design minimizes energy use.

- Used successfully in hundreds of machine shops.

- Most effective for droplet particles above 1 micrometer.

This form is the fastest way to get in touch with us.

A more detailed form, located here, will tell us what we need to generate a detailed quote.