Plastics Fabrication, Refining, Machining

Manufacturers who convert and refine plastics and resins use Tri-Mer pollution control technology to eliminate air contaminants, including methane, benzene and other VOCs; HAPs; sulfur and nitrous oxides, methanol and ethylene oxide. Downstream, plastics machinists use Tri-Mer Whirl/Wet dust collectors, the most effective option available for the collection and management of particulate 3+ microns and above.

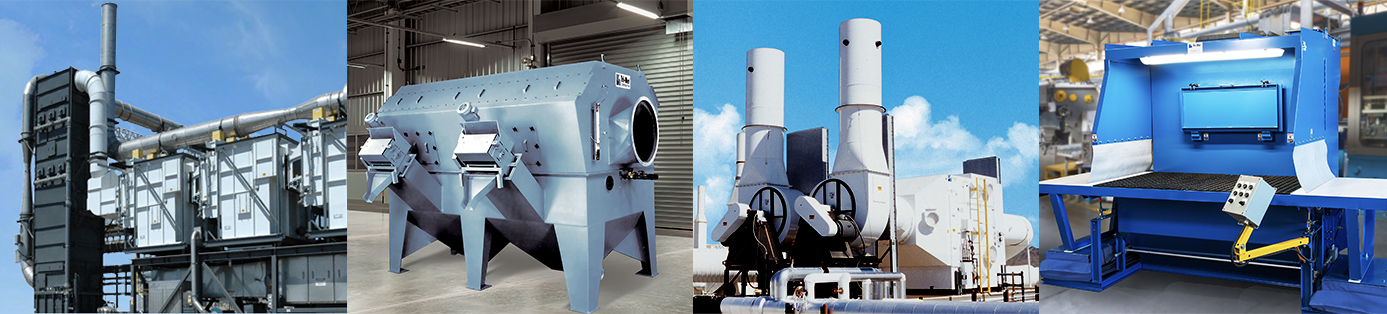

Depending on the contaminant species, production levels and capture/destruct level required, two Tri-Mer systems are most often specified for plastics fabrication and refining.

Cloud Chamber removes fumes and gases, including HCl, HF, HNO3, H2SO4, SO2, Cl2, and NH3. Simultaneously, it collects particulate from 0.1 to 300+ microns with greater than 99% efficiency.

Tri-Mer wet scrubbers remove inorganic gases, odors, fumes with extreme pH, chrome, NOx, fine particulate, mercury, HCl, Cl2, SO2, and HF. Tri-Mer wet scrubbers provide superb performance in scrubbing gases containing multiple pollutants.

Wet Scrubbers are built in two configurations:

Vertical Flow. Gas flow is counter to liquid flow; small footprint, round scrubber vessel, less costly to purchase and operate.

Crossflow/Horizontal Flow. Gas flow is perpendicular to the liquid flow; ideal for height-constrained applications; rectangular vessel. Slightly less efficient than vertical systems, although difference is minimal when treating water-soluble acids.

For plastics machining, Tri-Mer offers 4 dust collector options, including the MCD Whirl/Wet, which traps particulate at efficiencies of 98% to 99%.

Whirl/Wet uses minimal water, and requires only small water additions for make-up. It is self-cleaning, and prevents sludge buildup on the exhaust vent interior – a huge maintenance “plus.” It is suitable for virtually all particulate, whether soluble or insoluble.

For departments where downdraft tables are used, Tri-Mer has adapted its Whirl/Wet technology to produce the industry’s first adjustable downdraft table. Tri-Mer's Tri-Nomic Downdraft Table is a highly ergonomic commercial workbench that increases productivity and reduces fatigue. Its height-adjustable design minimizes stress and makes it comfortable for workers of all sizes to use, full shift. It is low noise, so it can be used near other workstations, and is ideal for drilling, grinding, deburring, sanding, and other subtractive processes.

This form is the fastest way to get in touch with us.

A more detailed form, located here, will tell us what we need to generate a detailed quote.