Industrial Dust Collector

Whirl/Wet® Industrial Dust Collector

Tri-Mer’s Whirl/Wet is industry's best alternative for the safe, predictable collection, and efficient management of combustible dusts. It is a practical alternative to mitigation devices such as isolation valving and fire suppression systems.

Whirl/Wet is a "workhorse" dust collector engineered for the continuous, reliable collection of industrial dusts 3 microns and larger. For companies who need to collect airborne particulate from manufacturing, processing, mixing and blending or packaging operations, Whirl/Wet is an efficient, field-proven alternative. It is widely used for facilities that process flour, corn and sugar, and those working with titanium, aluminum, and other exotic metals.

Every facility that generates combustible dust and is therefore at risk for static-related incidents, dust-related fires, flash fires, and explosion benefits from Whirl/Wet's superior, field-proven design.

Features & Benefits

95-99% efficient

for soluble and insoluble particulate

No internal moving parts

= NO replacement parts (nozzles, bags, pumps)

Self-cleaning

makes for easy maintainance

Highly energy efficient

= low operating costs

Low water use

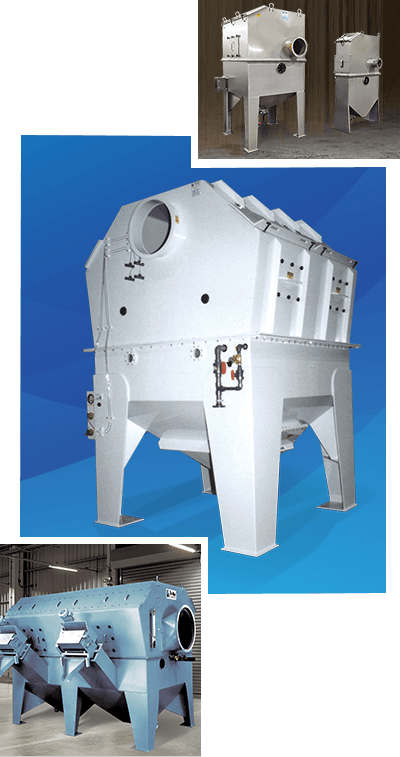

Whirl/Wet Configurations

Model MCD

500 to 50,000 cfm; 24/7; zero shutdown!

Model H

With available timed drain-down; also zero shut-down!

Model M

Manual, economical collector for low dust loadings.

How Our Industrial Dust Collectors Work

The dust collection system works by infusing dust particles with water, and processing through a fixed-position, dual-opposed blade system. Once the dust-laden airstream and liquid are mixed, a tangential airstream is injected through the lower blade assembly to intensify turbulence.

Rotation is accelerated, droplets in the airstream are processed through a mist eliminator downstream, and particulate is deposited on the bottom of the unit for recovery or disposal.

Applications

Whirl/Wet dust collection systems are effective for soluble and insoluble particulate. Whirl/Wet is widely used in applications from pharmaceutical manufacturing and snack food processing to metal grinding.

This industrial dust collector is frequently specified for the collection of coal, aluminum, fertilizer and sugar dusts. It satisfies the dust elimination requirements of stone finishing and battery manufacturing. And because it does not operate “dry,” it is ideally suited to applications involving volatile dusts. It is the leading dust collection system for combustible particulate solids, as well as situations where dust loadings are high - or highly variable.

Combustible Dusts and the Choice of a Dust Collector

Today, there is diminishing debate about whether dry collectors such as baghouses and cartridge devices, or wet dust collectors such as the Whirl/Wet are preferable when worker safety, facility protection and owner liability govern the decision-making.

A December, 2020 report published by the Fire Protection Research Foundation (Executive summary pdf available at www.nfpa.org) describes fires and explosions involving dry dust collectors in the US, Canada and China over a 10-year period. Among the study’s observations:

- Dust with sufficiently low minimum energy can easily be ignited by static electricity.

- Inadequate grounding or improper maintenance can lead to dry dust collector explosions.

- Friction-induced heating can cause dust temperatures to rise if there is sufficient accumulation. Two of the most disastrous fires involving dry dust collectors and described in the report were caused by friction heating.

- Spontaneous combustion (self-heating ignition) occurs in various industrial metals when they react with water. According to NFPA 654, Standard for the Prevention of Fire and Dust Explosions from the Manufacturing, Processing, and Handling of Combustible Particulate Solids, most water-reactive products are powdered metals. Aluminum, magnesium, titanium, and others form oxides by reacting with water. The reaction of sufficiently small particles of metal could start a fire if reacted with water (NPFA 654, 2013, n.d.). This was the central hypothesis of the largest yet fire incident involving dust collection. It took the lives of 185 people and destroyed an entire production plant in China.

- In another instance involving baghouses, it was estimated that the quantity of dust entering the filters was less than 1% of the minimum explosible concentration (MEC) in the filter bags. During bag cleaning, however, when workers would shake the collected dust in the filter bags, manually dispersed dust was capable of producing dust clouds with explosible concentrations (G.Li, 2016).

Conducting or commissioning a Dust Hazard Analysis is critical to understanding the kind(s) of dust a facility generates, and preparing the appropriate procedures for hazard mitigation where combustible and explosible dusts are present.

Wet dust collectors vastly reduce the risk of sparks, fire and explosion. They are a clean, practical solution to a vexing issue that all facilities face.

Tri-Mer has longest, best track record with this important hazard mitigation tool. Talk with us about how we can meet your dust collection needs.

This form is the fastest way to get in touch with us.

A more detailed form, located here, will tell us what we need to generate a detailed quote.