A Tri-Mer Whirl-X® was engineered for the safe, efficient collection of metal fines from grinding, sanding and deburring operations involving aluminum, magnesium, titanium, beryllium, uranium and other exotic metals.

The system is a cost-effective, high-performance alternative for these and similar applications that create an explosion hazard for dry and bag collectors.

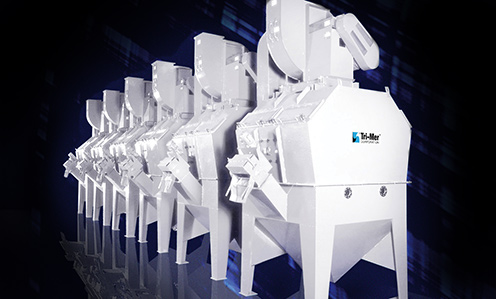

The Whirl-X industrial dust collector is manufactured in mild steel, stainless steel, and special alloys such as Hastelloy. It is also offered in all-polypropylene, a feature which prevents the accumulation of collected dusts, eliminates corrosion and minimizes maintenance.

Whirl-X captures 99.9% of all dusts five microns and larger. It can be ducted to multiple stations or sources, and is low noise.

Its advanced design does not use pumps, nozzles or bags - three costly and consumable components which are common to conventional collectors. It is self-cleaning, and, the patented whirl chamber has no internal moving parts.

Whirl-X uses very little water, an important factor in areas where utility rates are high. Following initial charge, the only water required is a small amount to compensate for evaporation and dragout. Systems can also be engineered to return air to the plant in some instances, reducing HVAC costs.

Whirl-X Systems are manufactured in capacities from 425 cfm to 50,000 cfm. Depending on size, reclamation requirements and other factors, three disposal alternatives are offered. Manual or timed-drain systems are offered for modest dust volumes; for highest volumes and lowest maintenance, an automatic conveyor dragout, “zero-shutdown” format is offered.

Tri-Mer manufactures a broad range of industrial dust collectors for metalworking and other process environments.