Whirl Wet Dust Collection System proves ideal for polishing operations.

Gabilan Manufacturing, Inc. (Salinas, CA) produces all the mufflers used on Harley Davidson motorcycles. Quality is paramount: the polishing is preparation for chrome plating – arguably the most critical finishing process for high-end bikes.

When new grinding and sanding equipment was installed, Gabilan considered several options for dust collection, finally choosing a cartridge system with spark arrestors.

Within a few weeks of installation, however, concerns mounted, as superfine metal dusts caused a series of small fires within the dust collector interior. A CO2 deluge system was added to increase the margin for safety.

Realizing the ongoing potential for problems, however, the company investigated other solutions. In addition to safety, life cycle costs, the feasibility of installing the unit out-of-doors, remote from the manufacturing area, and construction material options were considered.

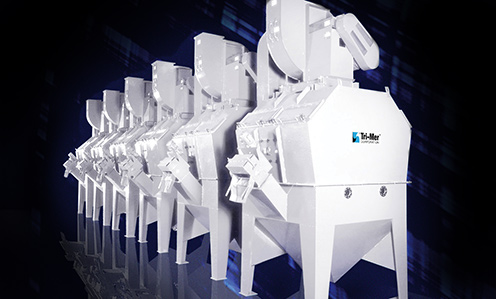

A decision was made to install a Whirl Wet. Key to the decision was its non-corrosive, all-polypropylene construction, and competitive price. In addition, the Whirl Wet does not have external pumps or recirculation systems, so installation out-of-doors was possible.

Water consumption, a major concern in California, is very low for the Tri-Mer system. In contrast to wet systems that rely on dynamic precipitation or flowing water films, the only water needed by the Whirl Wet after the original charge is that which is required to compensate for evaporation or drag-out. On average, the Whirl Wet uses 70-80% less water than other wet systems of equal capacity.