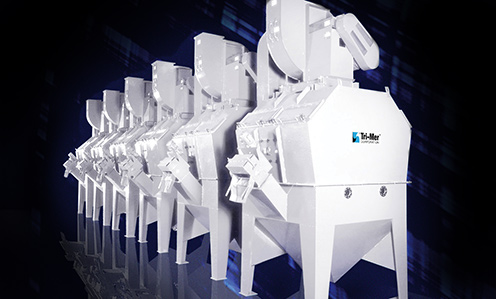

Natural stone manufacturer selects Tri-Mer Wet Dust Collector.

A manufacturer of natural stone and composite products for countertops, landscaping and commercial applications, chose Whirl Wet industrial dust collection technology. The system is a Model H, which is manufactured in capacities from 425 cfm to 50,000 cfm and higher. The system selected has a maximum 5250 cfm capacity; an automatically timed drain-down system provides efficient management of particulate.

Whirl Wet performs at 99% efficiency and higher for particulate 10.0 microns and large, making it ideal for marble, limestone and sandstone dusts. Water use is low, and the only water additions are those needed to compensate for evaporation.

Whirl Wet is self-cleaning, and energy generated inside the unit will not allow the system to clog under any operating conditions. The plugging (“blinding”) that plagues some dust collector designs is not an issue with the Whirl Wet.

This unit is all polypropylene, a material compatible with abrasive materials. Tri-Mer also manufactures its wet dust collector in mild and stainless steels, PVC and PVDF.